<< New Q&A

More Q&A, Part 12 >> Part

11 >> Part 10 >> Part 9 >> Part 8 >>

Part 7 >> Part 6 >>

Part 5 >> Part 4

>> Part 3 >> Part

2 >> Part 1 >> Gunwriters guns.connect.fi

Link page

Custom Search

Latest update 21.07.2001

G.O.W. Kickback:

Questions and Answer, Part 13

Answered by: P. T. Kekkonen

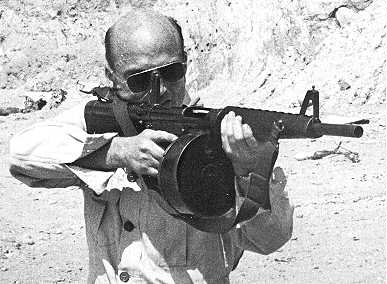

ATCHISSONIN RYNTOHAULIKKO/ Atchisson's

Assault Shotgun

I ran across this article http://guns.connect.fi/gow/haulikko.html

on the Atchisson Assault Shotgun. I was wondering if you have this article on-line

in English?

I ran across this article http://guns.connect.fi/gow/haulikko.html

on the Atchisson Assault Shotgun. I was wondering if you have this article on-line

in English?

Thank you: Gary.

: Sorry; there

is not an article on the AASG in English on the web, but there is a book "WORLD'S

FIGHTING SHOTGUNS" by Thomas F. Swearengen, (C) 1978, distributed by T.B.N.

ENTERPRISES (P.O. BOX 55 Alexandria, Virginia, USA), containing the whole story of many

assault shotguns, including the blowback prototype design of Maxwell G. Atchisson. I don't

know, however, whether these books are still available or whether the distributor of it is

still in business.

I received the permission to use material of this book (including reproductions of

illustration) from it's author 20 years ago (1981), but for articles publisheable in

Finnish only.

1107 MMI; PT

Subsonics for .243

Hi PT, I've enjoyed your information on the gunwriters web, now I have a question for you.

I would like to load some subsonic rounds for my .243. I have access to the Hodgon or

Winchester brand of powders, which powder to you recommend and starting grains for a 55

grain & 95 grain projectile? Is a packer of dacron required to hold the powder in

place? Your advice is much appreciated.

Regards; Luke, New Zealand

I know

that .243 Winchester is among those cartridges inherently prone to S.E.E. (Secondary

Explosion Effect), also known as the Reduced Charge Detonation (R.C.D.). Please, do

not try to design subsonic loads for .243 with ANY jacketed bullet. In theory it is

possible to develope a subsonic load with 83 grains cast lead-alloy bullet and the most

quickly burning (easiest-to-ignite) available handgun powder, but I cannot tell the exact

charges for subsonic .243 loads. Just some tip for Starting Load. All the rifles are

individuals and charges for "daily use" are exclusive. The gun-owner must design

them by test-shootings.

RECOMMENDED POWDER (IN NEW ZEALAND)

Neither Australian powder manufacturer, ADI, nor distributor of ADI AS 30N (a.k.a.

original CLAYS powder) is willing to give us any information about contents of their

products and especially handloading data for subsonic rifle loads with the powders they're

producing or distributing - even for the .308 Winchester cartridge, which is presumably a

most popular and among the least "tricky" one for subsonic loading, even with

the jacketed bullets. (Now talks FULL TWENTY YEARS of personal experience!). You may try a

combination as follows:

BULLET

Cast bullet LYMAN N:r 245 496 (nominal weight 83 grains) with a gas check, of almost pure

lead, lubricated and sized to the groove diameter of your rifle or just slightly bigger.

First try, whether you can use bullets of soft alloy "as cast", without resizing

at all, seated into the cases having slightly flared mouths. DON'T make too wide flare!

Active life of the case shall become shortened by repeated OVERDONE flaring and crimping.

Seat the bullet and adjust cartridge overall length to 63.0 millimeters (2.48") or

slightly longer: Bullet's point must touch upon leade/throat ahead of a chamber (show

visible rifling marks on the bullet when cartridge is extracted from the chamber without

shooting).

CHARGE FOR FIRST TRIALS

Try first five (5.0) grains/ 0.33 gram charge of Australian powder AS 30N (Original

Hodgdon's CLAYS! NOT Universal or International, which MAY be less easy to ignite). Use of

Dacron filling is not essential, but turn the muzzle of your rifle upwards before each

shot and then let it slowly towards the target. It is easiest way to keep the powder

charge in rearmost end of the cartridge case. (A trick of Finnish target rifle marksmen a

century or more ago. Nowadays generally forgotten).

BORE CONDITION

Start the test-shootings with a clean bore (jacket metal or lead fouling removed),

lubricated with very thin oil film. Preferable lube is an oil with added Teflon or

Molybdenium Bisulphide. "Break-Free" oil is tried and found suitable for

pre-test lubrication of a bore. During the shooting keeps bullet lubricant a "bore

condition" uniform enough. That's why just LYMAN No. 245 496 cast bullet is

recommended: There are five grooves around it's shank. All of them should be filled with

lubrication wax. Dip also bullet point into some lubricant (grease or oil) just before

chambering of cartridge.

"STEP UP" OF A CHARGE

You may increase the powder charge with 0.1 - 0.2 grain "steps" for search of

best accuracy, until the bullet velocity is "transsonic", giving a whiplash-like

noise, audible from direction of a target and no more from the rifle muzzle. Bullet

velocity is transsonic when some shots are dull "booms" and some others are more

high-pitched "cracks". When you are reached this velocity level (Mach 1.00,

slightly plus or minus. One Mach is the sonic velocity in ambient air in ambient

temperature) you must reduce your charge a couple of "steps", and here is your

subsonic load for daily use. Adopt the charge which shot the smallest group during

"stepping up" of test-loads, at least three shots with each charge.

POSITION OF CHARGE/ CASE FILLER

Keep always your powder charge in head-end of the cartridge, close to the primer's flash

hole or vent. Develope an instinctive habit to lift the rifle muzzle upwards before steady

aim. If you are unable to learn this simple trick, you must use a rumpled Dacron wadding

on your powder charge. Please Note: It is unnecessary to fill ALL the available empty

powder space with Dacron fibres. Use them just enough to keep the powder charge in the

reach of a priming flame: A fingertip-sized "carded" swab. When melted by the

powder flame and again solidified, the droplet of Dacron is not much bigger than a corn of

boiled rice.

SUPPRESSED/ SILENCED RIFLE

As a citizen of New Zealand you have presumably a suppressor mounted on your rifle. You

may use carefully rationed doses of Dacron even in the subsonic cartridges loaded for a

suppressed rifle, since the drop of melted Dacron fibres shall pass easily the bullet

passages of suppressor baffles and end-cap of the "silencer", which is truly a

SILENCER when the loads are subsonics, but just a suppressor or sound moderator, if the

bullet velocity is sonic or supersonic.

The very same device may be either a suppressor (sound moderator) or a true silencer, if

it is large enough and well-designed. Construction of a device may be very simple, if the

subsonic loads are used ONLY and they are loaded with correct brand of powder, generating

as low muzzle pressure as practicable and safe in use.

1507 MMI; PT

How long does an e-mail take!

Hello, I just received this e-mail at 22.40 on the sixth of July 2001. It is a reply to an

e-mail that I sent a month ago. Is this due to:

1) That you are a late replier?

2) That the e-mails take forever to get delivered to you, or me?

Please be so kind as to reply to this e-mail immediately so that we can find out what is

causing the delays?

Sincerely Lars

Ps: and i have gotten your snail mail and sent a reply by e-mail already!

1) Yes. Works

are jammed! (Just 24 hours per a day and seven days per a week). Sometimes I'll also take

some absurd stints, like translation of Mauser C-96

instruction booklet to archaic Finnish from almost as archaic German. (All this extra

toil, because I want to up-keep difference in kind of GOW/Finnish well ahead of the

Finnish printed periodical guns/ammo/hunting magazines).

2) Sometimes yes. I have not (and I cannot ever afford) the direct Internet connection to

my home. I'll be also unable to catch the messages or answer by the Web, because I'm

lacking even the elementary knowledge on the modern computer technology. "But you may

learn it from the books!" No, dear friend! It is impossible to learn anything from

the books, since I am able to comprehend less than every tenth word from some

"advanced MS Windows 95" user's handbooks. (Try to read my Finnish translation

from Mauser C96 käsikirja. Concratulations,

if You can comprehend 10% from it's text! Those lousy MS Windows handbooks are published

nominally in Finnish, but actually in text which I am unable to understand).

PT

WANTED: Gun parts

FRIENDS IN ARMS: I have been searching, so far unsuccessfully, for a front sight hood and

rear leaf sight for a Mannlicher Schoenauer Rifle (model 1952); and a rear peep

sight (part Nr. 7198, no longer made), for a Thompson Center, blackpowder Scout

Carbine. Do you have an idea where I might find these items?

Thanks & best regards, Jim

FRIENDS

IN ARMS. If you have these sought-after items for sale, please, tell by us. Give your

email address. Please Note: We must publish it on GOW/ Universal site. Your permission for

publishment of email address is ESSENTIAL! On your request, WITH YOUR PERMISSION we may

also publish your name and "snail mail" address.

1507 MMI; PT

NOTES & COMMENTS OF VISITORS

Hello Gunwriters,

Further to Yugoslav rifles and ammunition, a lot of Yugoslav ammunition was imported to

Australia at one time, mainly .303 British, 8 x 57mm German, 7.62 x 39mm and .223

(5.56mm). (We used to have a huge number of .303 No.1 MkIII SMLE rifles here before our

restrictive gun laws -- We still have a large number of them but you don't see them in

public any more. There were several problems with this beautiful, shiny Yugoslav ammo:

The .303 British:

This ammunition was marked PPU or PPYU MKVIIZ & MKVIIIZ. It lived up to it's marking.

(Late WWII British MKVIIIZ was a high powered round using nitrocellulose powder, not

cordite and it was designed for machine gun use in Vickers and .303 Brownings, not

rifles.) The Yugoslav projectile was heavier than a standard .303 British, 190 or 198

grains boat-tail (I think) instead of 174 grains and the powder load was VERY hot.

I think the problem may have been twofold, the powder was developed and tested in a cold

climate, and my guess is the load was higher because it was originally intended for

military export use and the probably wanted it to drive tired old .303 Browning

Machineguns, Vickers and BRENs in their export markets in third world Africa.

In a .303 SMLE No1 MKIII it would stretch the action if used too often. It was OK in a

good .303 No.4 action, but I have seen it blow an extractor out of a .303 No.4 which was a

bit worn and loose.

The 7.92 x 57 mm ammo seemed OK, but most K98 actions are very strong anyway.

The .223 was a REAL problem, it was not made to standard US SAAMI specifications and it

had an extremely hot load. It was OK in some bolt actions but it destroyed automatics. One

problem was the primer cups were too brittle and they'd perforate when used in a Ruger

Mini-14 or an M16. Bulged heads, split cases, loose primers and bulged barrels all

happened. I have seen a full-auto 5.56 mm SMG disintegrate while using this ammo.

A problem which you probably wouldn't get too often where you are is that ammunition is

very temperature dependant. In Australia if you leave ammunition in the sun on a hot day,

breech pressures can go off the scale and accuracy will suffer markedly.

Similarly, ammunition designed for the tropics may not cycle a weapon in the arctic or may

not ignite powder correctly under extreme cold, causing low powered rounds and short

feeds, particularly in 9mm.

Anyway, that's all on Yugo ammo. Stay away from them. Their rifles are good. (Their

Simonov variant, AK variants, their K 98s and their 'Dragunov') but stay away from their

ammo, it's far, far too hot.

As for the Serbs releasing weapons, I think that's unlikely, unfortunately they're all far

to busy using them on each other and with the promiscuous way they fire them there won't

be an unworn barrel left in the area.

Truth is the 7.62mm Nagant is a very good long range sniping calibre with good ammunition.

(Some of the old Soviet Bloc ammunition is terrible!)

I've done very good shooting with a Russian 7.62mm Nagant Sniper despite the terrible

stock and single stage trigger. Mine was mint new condition and it had a lapped and

air-gauged barrel courtesy of the Soviets.

If you reload with care and use .303 British projectiles (They're the perfect size,

.311") it will shoot one MOA all day.

Regards,

Sherro. (Australia).

Bullets shot backwards

Hi PT, Hope this finds you well. I believe at one time you mentioned that some military

users of subsonic ammunition would convert their ammunition by loading the bullets in

backwards, with a reduced powder charge, for greater "punch" and accuracy. Do

you have any more details on this method? Did they lubricate the bullets as we do with the

"suputin" rounds? Thanks for your help.

Dave.

Military

users of reversed bullets were Germans during the 1st World War! Soon after the arrival of

British tanks in Cambrai, France, 15th September 1916, they were found an Armor Piercing

projectiles available for each rifleman in the trenches. (The real AP bullets were issued

to the snipers only). Quotation from the booklet "KNOW YOUR ANTITANK RIFLES" by E.J.

Hoffschmidt, published by Blacksmith Corporation:

"Like most secret weapons, the tank had its bugs. They were mechanically unreliable

and several were soon captured by the Germans. After some hurried testing, they found that

by simply reversing the direction of the standard infantry rifle bullet in the cartridge

case, it would penetrate thru the British tank armor".

This German "standard infantry rifle bullet" was a flat-based, pointed FMJ

projectile for 8 x 57 mm Mauser rifles and machine guns with mild steel (I prefer the term

"iron") jacket, weighing ten grams/ 154 grains. Nominal muzzle velocity of it

was ca. 2920 feet per second (890 m/s), but when reversed, it might be 900+ meters per

second, because the powder charge was not reduced. Nominal maximum chamber pressure was

3100 atmospheres, but because of the compressed powder charge, it was presumably about

4000 atm, when those improvized "anti-tank loads" with reversed bullets (seated

almost the base flush with case mouth) were shot. Fortunately to Germans, action of Mauser

Model 1898 kurz rifle is able to stand occasionally 5000 atmospheres of chamber pressure

if the cartridge case is able to seal it without split of it's head.

It was rather a rule than an exception that the rifle bolt was stuck tightly. It was

needed to beat open with a boot sole or fire-wood. Germans cursed the actions of Mauser

rifles when they fed the blunt-pointed cartridges into chamber (essentially from the

magazine), but they blessed the sturdy and broad extractors which enabled removal of stuck

case without extractor-hook breakages or case rim broke-offs.

Use of reversed bullet to perforate 8.2 mm thick armor plate of earliest tanks was based

on an elementary fact: You need considerably less energy to punch/ "die cut" the

hole through a plate than to puncture it with a pointed drift, especially that of rather

soft material like German Spitzer bullet, which must make a hole with diameter 17 to 20 mm

through armor plate when struck point-on, demanding 1000+ m/s STRIKING velocity, but mere

8.5 to 9.0 mm when struck base-on and therefore acted as a wadcutter. Plates were of

face-hardened mild steel, riveted on the angle iron skeleton frame. There were 2 - 3

millimeters wide slits between the plates, and each rivet was an "Achillean

heel" of the first tanks. British tankers learned very soon to wear wire-mesh

"tanker's mask" with goggles, when some colleagues of them were lost their

eyesight by the spray of molten lead droplets and fragments of hot iron.

Finnish gunwriter VELI NIEMINEN (passed away in 1936), a contemporary secretary of Finnish

Shooting Association (Suomen Ampujainliitto r.y.), wrote on his "AMPUJAN KASIKIRJA/

Handbook to the Shooter" published in 1926 about the boat-tail FMJ military rifle

bullets: "They are about as accurate when shot reversed as when shot point

forwards". Author V. Nieminen mentioned also some loads with reduced charges in this

book, and the special powders like DuPONT de Nemours IMR 15˝ and 17˝ (with added

powdered tin) were also familiar to him, but he became goofed when using them and wrote:

"After few shots, the bore of my rifle was sooty; tarnished from the throat to

muzzle. It was very difficult to remove those dull grey remains of incompletely burned

powder."

In 1989, when some Finnish bench-rest shooters loaded and shot cartridges with Hodgdon's

H-870 spherical powder, they lamented that: "The perkeleen*) Yankee powder corroded

my rifle bore after a couple of shots loaded with it!". I had a chemical analysis of

H-870 in my possession. So I could console those benchresters: "Don't worry! Your

rifle bore is not corroded or eroded, but just lined with a very thin coating of metallic

tin. Powder H-870 contains a small percentage of Cassiterite (stannic oxide), which is

reduced by the loss of it's oxygen.

Don't remove this dull grey coating from the bore, although it may look displeasing: Just

polish it with a fine steel-wool! It prevents corrosion and copper-alloy fouling, just

like the pewter anti-fouling rotation rings of heavy artillery shells. Powder H-870 is

designed for the cartridges of rapid-firing Vulcan machine cannons. Therefore this

anti-fouling material (Black Cassiterite) is essential in it's composition".

*) "Perkeleen" = "Satanic; Diabolic". PERKELE was originally

PERKUNAS, a Lithuanian deity of the thunder. This abused name was adopted to the Holy

Bible, when it was translated to Finnish: We got a very strong new swear-word to our

language in 16th century.

Some benchresters, who were done their military service in the Coastal Artillery or other

heavy artillery, did believe in my scientific explanation. Some others trusted in

"Gothic stories" of VihtaVuori's salesmen and dummies: Several barrels of

bench-rest rifles were renovated unnecessarily. "O Sancta Simplicitas!".

VihtaVuori yields today N500-series of powders, with nitro-glycerol surface coating, which

was "cause of corrosion and erosion" according to the horror-stories told a

decade ago. I don't know, whether N500 powders contains Cassiterite or not: We have no

friends amongst the producers or dealers of firearms, ammo or propellants anywhere on the

Globe, and we can no more get information about the compositions of the new propellants

directly from manufacturers or distributors of them.

There were some Finnish moose-poachers in the late 1930s, who knew the trick of reversed

bullet. Moose population was, however, very small and moose poaching was not profitable

trade in Finland, except in the regions close to the contemporary Russian border in

Carelia (robbed by the Russian communists in 1940 and another time in 1944. This pillage

was applaused also by the allies of Red Russia in 1947, when the so-called "Peace

Treaty" - risum teneatis, amici? - was signed in a city of Paris between Finland and

the "Allies"). Most Carelian professional poachers shot mooses with sawed-off

shotguns, loaded with coarse black powder and spherical lead bullet - or a cylindrical

cast (solid!) lead "slug". Dull report of a shotgun attracted less notice than

"cracky" blast of rifle, and the poacher should not arouse attention.

I have no information about military use of reversed bullets during our wars 1939 - 44.

(Captured Russian cartridges with explosive/incendiary ZR bullets were plentily available:

No need for "Dum-Dumming"!). I re-discovered this reversed bullet trick twenty

years ago, now especially for subsonic loads and boat-tail bullets Lapua D-46 with a

stepped boat-tail. (I could publish the trick in 1982 by a most popular Finnish outdoors

hobby magazine! It was an era of miracles: Handloading of subsonic rifle cartridges is

today a "TABOO" on the printed matters in Finland). Idea was found from book of

Veli Nieminen, who was, however, never tried this trick for subsonics. (He didn't actually

test-shot "supu-loads" in 1920s and 30s, but just somewhat reduced charges with

rifle powders and cotton-filled cases).

Today we have very good .30 caliber bullets for reversed loading, Lapua FMJ

"Lock-Bases" with almost hemispherical base and a sharp point. Our test-shooter

Markus (MPP) has observed that the Ballistic Coefficient of Lock-Base bullet is higher and

trajectory is more straight when it is shot reversed at subsonic velocity. Accuracy is

also sometimes improved and at least as good as that of point-forwards propelled bullets.

The shape of reversed Lock-Base projectile is almost ideal for conquer of air resistance

at subsonic velocity. A sharp bullet point has no remarkable superiority to ogival or

hemispherical point, but stream-lined bullet's base shall reduce the "suction air

resistance" considerably and so add the Ballistic Coefficient of a bullet at the

subsonic velocity level.

This observation is actually almost 160 years old: Improved "Lang Blei"

(= "long lead") bullets for Prussian bolt-action Dreyse rifles were

"bird-shaped", with a shorter point than the streamlined boat-tail base and no

cylindrical "shank" at all. Designer Johann Nicolaus von DREYSE was adopted his

idea from the body shape of a pigeon or some other bird.

Those Finns who knows the trick of reversed bullets know also beneficial effect of

bullet/bore lubrication. Molybdenium bisulphide coating of bullets is a popular procedure

here, but use of pure copper as a jacket material and electroplating or

"electroless" chemical plating of bullets with a thin coating of nickel may

become a standard treatment in the near future. It is also an old German invention:

Nickel-plated pure copper was found to be an ideal jacket material in tests of SPANDAUer

ARSENAL (1886 -87) but refined copper was too expensive stuff in those days for use as the

bullet "envelope" metal.

Observation of Germans fell into oblivion, but it is just a "Sleeping Beauty", I

think so! Today are .30 caliber Sako 145A bullets jacketed with refined copper and it is

easy to electroplate shanks of them in a drinking glass with a 1.5 Volt dry battery. It

takes mere three seconds of time to plate a bullet with a proper nickel coating.

(Experience talks..!). Alloy of copper and nickel was also adopted in many countries, but

it was less succesful jacket material - especially when the velocities of military rifle

bullets exceeded velocity ca. 750 meters per second: Metal fouling became a scourge.

Germans adopted iron jackets, plated with cupro-nickel, copper or the Gilding Metal. They

also re-dimensioned bores of Mauser rifle, shawing the rifling grooves 1˝ times as deep

as the grooves of previous Model 1888 Commission Rifle.

Non-metallic jacket materials (polymers) are also promising option, when ammunition

industry shall sometimes start to produce special projectiles for handloading of subsonic

rifle cartridges. "Polymer Nr. 66" (trade-mark Nylon) is a most suitable

material for this purpose, as far as I know. It is already tried as the jacket material of

revolver bullets ("Nyclad") and in the "cages" of high-velocity

compressed-air rifle projectiles ("Prometheus"). Shape of the bullets for

subsonic rifle loads may become also uncommon, but they shall have usually patterns on the

pages of firearms history, which is always the inexhaustible source of "revolutionary

new inventions and innovations".

2706 MMI; PT

Velo-Dog revolvers

1: If you have any information about old revolvers (or sites about it), popular named

"Velodogs", because was used by bikers to protect himselfs ot the dog

attaks, please answer me in your page.

2: Also I want any information about websites refered to old test banks for guns and his

typical marks for each gun or type of guns. Here, in Argentine Patagonia, it is not so

easy find this kind of information. Thanks so much.

JORGE, CHUBUT, ARGENTINA

1: In general,

I must confess once again that I have not a direct contact to the Web sites, and no skill

to search any sites. Also: I have not enough income to acquire a Web contact, and I'll

never get it. On the other hand, I'm lacking enthusiasm or even the lukewarm attachment to

Information Technology and the expensive electrical devices or the computer programmes,

whose generation lasts just six months. (My "typewriter" computer is about

fourteen years old. It's word processing program is ca. 28 years/ 56 generations old

Finnish TEKO Original. And I'll never learn more about electrical information processing

than just those essentials I need. Please; never more ask from me the web sites!).

Re Velo-Dog revolvers and cartridges I have a lot of information. Several years ago I

suggested a Brazilian firm CBC to re-enter upon production of 5.75 mm Velo-Dog cartridges

for ca. a million of "hungry" Velo-Dog revolvers (usually of very high quality

and in very good shootable condition), possessed in Continental Europe. Million of them?

Yess! I found from a book "ASE-ATLAS" by Russian Alexandr B. Zhuk

almost 90 drawings of V-D revolvers. This book is publisheded in Finland. Text is in

Finnish. Book is available from book sales of ASE-lehti. It contains thousands clear

drawings of handguns and shoulder arms, being a "Number One firearms identification

book in the world". E-mail address of world-wide distribution is:

kirjamyynti@aselehti.fi . List price equals US $ 38:60 in Finland (plus postage).

In our country the Velo-Dog revolvers were and are still rarities even in the public or

private collections, while those cheap 7 mm LeFaucheux pinfire revolvers are common and

they were still more commonplace guns about a century ago, when here were pinfire

cartridges plentily available and no kind of "gun control" precluding possession

of handguns until November 1918. Finnish ex-emigrants, returning from USA, brought also

cheap centerfire pocket-sized revolvers to the "old country", but these handguns

were chambered for "American cartridges".

No American manufacturer produced revolvers chambered for Velo-Dog cartridge, because it

was a French innovation (of Galand; 1894). "N.I.H. syndrome" is an universal

scourge: "Not Invented Here = Worthless for any use here". Three American

ammunition companies loaded, however, V-D cartridges presumably for the European export.

The 5.75 mm V-D cartridge is interesting, not only as a revolver ammo, but also - and

especially - a cartridge for chamber adapters of existing centerfire weapons and those

equipped with a rifled barrel liner. Why? Because the case diameter is small, about like

that of .22 Winchester Magnum Rimfire, but the cartridge is still a CENTERFIRE one, using

standard-sized Boxer primer, and it is therefore RELOADIBLE. CBC has not received my

letter, or they are suffering from "the SAKO Syndrome"? (The most arrogant

Finnish firms have never sent answers to my letters, even the most friendly messages).

I must correct the usual delusion about name "Velo-Dog": Revolvers and

cartridges were not designed for shooting of dogs, but all the unjustified attackers,

including the robbers, rapists, burglars and muggers. For the protection against dogs were

already available very clever loads for pin-fire (5 mm, 7 mm and 9 mm LeFaucheux)

cartridges: Paper capsules filled with "dust-sized" lead shots, diameter less

than one millimeter and powdered CAPSICUM ANNUUM pepper. Oleoresin of Capsicum,

"OC", is recently found to be more efficient than any synthetic chemical

tear-gas. In Finland and Sweden this spice is known as a "Cayenne Pepper" and in

America as a "Hot Chili"; a most acrid spice available from all supermarkets.

Velo-Dog cartridges had Full Metal Jacketed bullets with a risk of over-penetration

through a dog, but not an immediate effect. A dog, blinded and lost it's skeenest scent by

the dust-shot & pepper load didn't continue it's attack, but especially a rabid dog

didn't even note a hit or even several fatal hits of tiny 5.7 mm full-metal jacketed

bullets, unless they were hit into it's central nerve system. A dog was usually able to

bite the defender before it's detained death and infect the biker with rabies, if it was

itself infected with hydrophobia. For chase-away of dogs those V-D revolvers were actually

about the LEAST suitable contemporary firearms..! So, why the name?

Velo-Dog revolvers were variants of earlier Bulldog revolvers. Ending "-dog" of

a compound word derived from it. These guns were recommended to velocipedists (bikers),

because of the always existing double-action mechanism (sometimes double-action only) and

a mild recoil which didn't kick the biker down from the saddle, but those guns were also

fit for home-protection and self-defence in general. That word "Velo-" may also

be a derivation from the Latin word "velox", as the jacketed bullet could be

shot with higher muzzle velocity than a lead bullet of usual contemporary snub-nosed

Bulldog revolvers or (especially) the pin-fire handguns. Arrival of smokeless powder was

also topical in 1894. Most French V-D cartridges were charged with "Poudre

Blanc"; it's variations "Poudre J" (= "Jaune"; i.e. "yellow

powder") or "Poudre S" (irregular flakes, looking like tiny silver chips),

from the very start of their production in France.

These powders were designed in 1892 by inventor of smokeless powder, Paul Vieille, for 8

mm "Lebel" revolver cartridges. "Silvery powder" is still made in

Czechian Republic and sold as an American powder "AA No. 2" distributed by a

firm Accurate Arms, made by a French licence in Prague Powder Manufacture since 1919.

Nominal muzzle velocity of V-D cartridge bullet was mere 198 meters per second (British

Kynoch load) or 230 m/s (U.S. Remington & Peters loads). Actual velocities are

impossible to estimate, because barrel lengths of revolvers varied. Weight of round-nosed

bullet was 45 grains/ 2.92 grams in British and American loads, but 3.0 grams in original

French loads, which were slightly more efficient than British or American ones. Bullet and

cartridge was designed to penetrate even the robust attacker (human being; not a DOG)

deeply enough to incapacitate or kill, even if the bullet perforated a thin bone, sternum

or a rib.

Some earlier or contemporary revolvers (especially 5 mm and 7 mm pin-fire guns) were

unable to push their bullets even to the subcunateous tissue through heavy clothing.

Jacketed roundnosed bullet of Velo-Dog made a narrow but straight and deep wound channel.

Despite of it's slow muzzle velocity from revolvers with a barrel sometimes shorter than a

cylinder, the bullets shot to ventral side (chest or stomach) of an attacker were

sometimes found from subcutaneous tissue on a dorsal (back) side (unless they were

perforated a body entirely). These traumatologic observations were got usually from the

post-mortem examinations of FELONS; never from the autopsies of DOGS.

5.75 mm Velo-Dog cartridge had an extra-long case and considerably large powder space

compared with .22 Long Rifle rimfire or even .22 WMR cartridge. Charge of smokeless powder

was about par with .22 LR High Velocity load. Bore friction of jacketed bullet was

compensated by the reduced charge (compared with available powder space). Maximum allowed

chamber pressure of V-D cartridge was mere 750 atmospheres. Maximum pressure of .22 LR

cartridge is 1800 atm and that of .22 Winchester Magnum Rimfire is 2000 atmospheres.

Case rim of V-D cartridge is, however, solid and thick enough to withstand easily at least

as high pressure as that of .22 WMR case - or many reloads to the "specific"

V-D's pressure level. Majority of Velo-Dog revolvers were built strong enough to allow

safe shooting with a muzzle pushed to contact on the body of an attacker. Muzzle blast

completed effect of a projectile: It tore a scorched entrance hole just like an explosive

bullet, but with a deep penetration of full-jacketed projectile. The solid combustion

residues of "Poudre J" contained also toxic water-soluble barium salt. That's

why the chamber/muzzle pressure was kept on the "lower than necessary" level.

Traditional explosive revolver bullets in 1890s were

also able to tear large scorched wounds, but they lacked penetration and failed many times

to detonate because of their low striking velocity. Caliber of explosive revolver bullets

was usually about 12 millimeters (.455 Webley or .476 Enfield) and the guns shooting them

were not pocket-sized handguns like Velo-Dog revolvers but the big military "belt

pistols". Police revolvers like Webley & Scott

"R.I.C." had too short barrel to generate high enough velocity for

regular detonation of bullet's fuze. (Tested by us? Of course..!).

Traditional explosive revolver bullets in 1890s were

also able to tear large scorched wounds, but they lacked penetration and failed many times

to detonate because of their low striking velocity. Caliber of explosive revolver bullets

was usually about 12 millimeters (.455 Webley or .476 Enfield) and the guns shooting them

were not pocket-sized handguns like Velo-Dog revolvers but the big military "belt

pistols". Police revolvers like Webley & Scott

"R.I.C." had too short barrel to generate high enough velocity for

regular detonation of bullet's fuze. (Tested by us? Of course..!).

Photo: Caliber .455 Webley & Scott "R.I.C."

Maximum dimensions of 5.75 mm Velo-Dog cartridge are:

Case length...................29.60 millimeters

Cartridge overall length......34.30 mm

Case mouth outer diameter......6.30 mm

Case rim diameter..............7.80 mm

Case diameter ahead of rim.....6.42 mm

Bullet diameter................5.74 mm

(Source of information: West-German Firearms Act, 1.3. Anlage III zur 3. Verordnung

zum Waffengesetz, attested in September 13th 1976. Table is based on the European

C.I.P. standards). V-D cartridge is not standardized by American S.A.A.M.I.

specifications. American firms Remington, Peters and Winchester loaded it until the Second

World War, but no more later.

2. I am unable to comprehend your term "test bank". Is it a "proof

house"? Stamps on the officially proof-shot firearms are known as "proof

marks". It may take a year (or years) to list all of them! Example given: Germany

had/has many proof houses and the proof marks were varying from time to time. Too much

bustle to search proof marks of all (or even most) proof houses on the world.

PS: Are the Argentinian "gauchos" still carrying the old 12 mm and 15

mm LeFaucheux pin-fire revolvers? If so: Where the cartridges for them are loaded

nowadays?

2406 MMI; PT

Lost "snail mail" letter?

Hello, PT I would just like to know if you have received my payment?? If it is not too

much trouble for you I would really like a reply to this e-mail.

Sincerely, Lars; Norway

Your

letter, stamped in V:gli, Norway 24.4.01 arrived to our P.O.Box in 26.04.01. Many thanks!

"Snail Mail" is considerably more swift and (especially) more sure than E-mail.

We have tried to send a message to your E-mail address at least three times since April

2001, but you have presumably not get any of them?! Anyway: Welcome to the

"Club" of Privileged Visitors!

For those visitors willing to support our activity I must tell bad news, but also good

news. Bad ones first: We tried registration to "Paypal" currency transfer

system, but registration is impossible in Finland if a company or private person has not

an International Credit Card (like VISA). And just the solvent companies or persons with

an abundant regular income are entitled to get a Credit Card.

Good news: Exchance of cash money (bills/ banknotes) is less expensive in Finnish banks

than I have feared. Banking charges for honouring of international cheques or money orders

are, however, more dear than is our annual fee. It is also possible to exchance many

foreign currencies; not US dollars only, but also paper money of most European countries

(with some exceptions like Russian roubles). Canadian or Australian dollars are also easy

to chance here to Finnish Marks - or to Euros after 1st January 2002 when the Euro shall

become an official monetary unit in Finland.

2406 MMI; PT

Yugoslavian 7.92 mm Dragunovs

There is a very serviceable version of the Dragunov made in the German 7.92mm

(8mm) Mauser calibre by what was originally Yugoslavia. They also made and repaired MG42

Machine guns and 7.92mm Mauser rifles. The Yugoslavian version uses a telescopic sight

very similar to the original Russian version.

As a bit of historical information: I'm reliably told that the CIA paid a very large sum

of money for their first Dragunov sample which came out of what was then Rhodesia, via

Zambia. (About $25,000!). Now they're down to reasonable prices.

Sherro (Australia).

Editor's

comment: Many thanks for information. Yugoslavian sporting rifles manufactured by Crvena

Zastava plant were known in Finland, but not too many of them weren't imported before

start of Yugoslavian civil war. Cartridges loaded mainly by Prvi Partizan,

Titovo, Uzice, (headstamp "PPU" with Cyrillic letters), were well-known here.

Disintegration of Yugoslavian Federal Republic and a civil war ended import (export?

production?) of Zastava bolt-action rifles, but at least a part of Zastava's pistol

production seems to be re-established in Greece. I have no idea, whether import of PPU

cartridges is started again here.

Dragunov rifles were presumably produced "for official use only", but let's hope

that ex-Yugoslavians shall start the export of at least surplus Dragunovs. In the Western

World that 7.9 x 57 mm JS (Mauser) cartridge is presumably slightly more common than the

7.62 x 54R Mosin-Nagant, but Dragunovs chambered for .308 Winchester may become to

production for export in some sunny day? There isn't too big physical difference between

.308 Win and 7.9 x 57 mm cartridges. Once again: Thanks for the information.

0706 MMI; PT

Gun Shows and other "Cat's Christenings"

in Finland

Please excuse my ignorance, but I am a visitor in Finland. I wonder where I could find a

list or program of gunshows and militaria markets scheduled to take place in Finland in

2001? Will appreciate any suggestions.

Sincerely: Tom

Please,

excuse our ignorance, but we are presumably the least "commercially tended"

media in the Western World! But you may ask the schedule list of gun shows & militaria

markets from the Editorial Office of "ASE"

magazine. E-mail address is: aselehti@aselehti.fi . I presume that they have a list of

those shows/ markets and other "Cat's Christenings" until the end of this year

2001 in Finland and Scandinavian countries.

0806 MMI; PT

US Rifle Krag & Joergensen .30-40

I restocked a Krag and upon glass bedding the action found that the guide studs would not

enter, so I layed the action in the stock and screwed the studs in place and clamped it

down. The guide studs on a Krag are not straight and parellel as in most other rifles, the

studs get closer as you come to the ends. The action can't bend so they had to be made

that way. What was they're intention, which one should be pulled in first? I'm at a loss.

Can you give me some advise?

Thank you; John from Idaho, USA

I have

never disassembled .30 caliber Krag rifle (or it's Scandinavian variations). From "The

Gun Digest Book of Exploded Firearms Drawings, 3rd Edition" by Harold A.

Murtz I found illustrated parts list of Krag action, but there were no parts known as

"studs". I presume, you're meaning trigger guard screws, if not a lug below the

tail of receiver tang. It's rear end seems to be somewhat askew on the drawing. From the

book "Firearms Assembly/Disassembly, Part IV: Centerfire Rifles" by J.B.

Wood I found an advise, you'll presumably asking for: (Disassembly) "Remove the

vertical screws on the underside at the front and rear of the trigger guard. Take off the

guard downwards, and separate the action from stock. Take care to move the action straight

upwards during removal."

There are no special "tips" or "tricks" mentioned on this book for

reassembly of Krag rifle, other than those for reassembly of magazine and the bolt. So you

may put the stock and barreled action together in reversed order STRAIGHT DOWNWARDS,

reassemble the trigger guard, and turn the vertical screws to proper tightness, presumably

the rearmost screw first.

The rear end of a magazine seems to act as a recoil lug of Krag, and the barrel bands

seems to keep barrel and fore-end of a stock together. No other screws but those fixing

the trigger guard are found from the list of parts. They squeeze, of course, also the

action on the stock.

2805 MMI; PT

Villar Perosa and FIAT machine gun(s)

Dear Pete

I've seen your answer in Part 4. Questions & Answers Until 05-12-1999 about "Origin of AK assault rifle and 7.62 x 39 cartridge" by John W. I

found You are not correct about Villar Perosa Mod. 1915 sub-machine gun. For sure

it's not a scaled-down version of Fiat (Revelli) Mod. 1914 machine-gun as you can

see in the pictures I'm sending you. More the Villar Perosa fires 9 mm Glisenti

pistol cartridges, while Fiat fires 6.5 mm Carcano rifle ones.Also the chargers, as you

can see, are completely different. The V. P. submachine gun fires 2500 - 3000 rounds per

minute, the Fiat only 400 - 450 ones.

Regards, Ferrante, Italy

Your

comment is correct! FIAT/Revelli machine gun is entirely different from Villar Perosa Mod.

1915. But I hadn't FIAT/Revelli gun Mod. 1914 in my mind, although Abiel Bethel

Revelli-Beaumont could be a co-designer of another (less-known) Italian machine gun.

Action of Revelli Mod. 1914 is a combination of short recoil and delayed blowback, very

similar to action of Glisenti Mod. 1910 pistol; discovery of two Swiss mechanics,

Paul Haensler and Pierre Roch in 1905. Design of pistol Mod. 10 was,

however, "completed" (read: spoilt) by A.B. Revelli-Beaumont. Siderugica

Glisenti was just a manufacturing company of these pistols.

Barrel moves a short distance back. The breech-block moves backwards and so away from

breech-end of the barrel without positive locking by a swinging lock-lever, before the

chamber pressure is low enough for easy case extraction. Charger of Fiat/Revelli was a

cluster of box magazines, fixed together side-by-side.

The gun was water-cooled, usually mounted on a heavy tripod. Fabbrica Italiana di

Automobili, Torino (FIAT) produced, however, also other machine guns - including

Villar-Perosas; but not ONLY designs of Abiel B. Revelli.

Example given: Subsequent manager of FIAT company, Giovanni Agnelli, designed a machine

gun with a simple construction and a "too much too early" improvement: Fluted

chamber (or powder gas lubrication of chambered cartridge), already BEFORE the First World

War and several years before introduction of Villar Perosa. Chambers of many Italian

machine guns with delayed blowback actions were lubricated with oil for prevention of case

breaks. (Idea of lubed chamber was invention of German Andreas Wilhelm Schwarzlose, who

designed a first practical machine gun with delayed blowback action in about 1900.

Cartridges of earlier Austrian Karl Salvator & Dormus "Skoda" machine gun

were also dipped in oil before they were dropped into a gravitation-feed charger of the

gun, which was not yet a practical weapon).

"Pater Noster in Exelsis: Dona nobis Maxim sclopetum!" (Latin:

"Our Father which art in Heaven: Give us a Maxim gun!"). This was a morning and

evening prayer of religious Italian warriors during the First World War, according to the

contemporary anecdote. Revelli Mod. 1914 was never a popular machine gun among it's users:

Too many jams and broken shells! The rear end of a breech-bolt horrified also the most

timid machine gunners, although the recoil buffer between "spade handles"

stopped positively it's movement rearwards.

"A grown-up elder brother" of Villar Perosa Mod. 1915 was NOT the best-known

design of A.B. Revelli, but S.I.A. machine gun. According to Ian V. Hogg: "Designer

G. Agnelli was responsible for the design of SIA machine gun. The initials are derived

from the (former?) manufacturer, Societa Anonima Italiana G. Ansaldo, Armstrong &

Company. SIA was a retarded blowback gun in which the bolt was locked by the forward

movement of the firing pin, which rotated the bolt as it struck the cartridge cap. Like

all retarded blowback guns, the SIA suffered from difficult extraction.

Agnelli solved this problem by cutting longitudinal grooves or flutes in the gun chamber

so that a small amount of gas leaked past the case mouth and 'floated' the case to prevent

it sticking. He patented this idea, which has been widely used in subsequent weapon

designs. Agnelli's designs and patents were taken over by the Ansaldo company *shortly

before the First World War*, but the gun was not developed into a practical weapon until

the 1920s, by which time there were several other and better designs available. A small

number were bought by the Italian Army for training". (Quote from "The

Illustrated Encyclopedia of FIREARMS" by Ian V. Hogg, 1978. Straight quotes are

permitted in early 1980s by copyright holder, Quarto Ltd.).

If A.B. Revelli was not a co-designer of pre-WW I SIA gun, his Villar Perosa Mod. 1915 was

not only a scaled-down variation of Agnelli's gun, but a plagiarism of SIA. Unfortunately

the later history of firm A.A. & Co. is unknown to me, but as far as I can recall, it

was merged to a company known as SAFAT (Société Anonyme FIAT Armamente, Torino), which

was later sold to Ernesto Breda company, when FIAT withdrew from firearms business. Those

SIA guns sold to Italian army were presumably made by SAFAT, when it was still an armament

division of FIAT.

Delayed blowback action of Agnelli's gun was copied by Pietro Beretta company (licensed

copies of V-P; single guns with buttstocks, production models 1918 and 18-30), in

Soviet-Russia (Degtaryev submachine gun model 1930; some prototypes were made) and in

Finland (prototypes of AL-43 assault rifle).

I have seen pictures (including most interesting sectional drawings) of SIA machine gun

only on the rare and expensive book "The Machine Gun" by Chinn, (USA). I found a

section drawing of Villar Perosa's action from the "Textbook of Automatic

Pistols" by R.K. Wilson (England). About six years ago I could borrow two volumes of

"The Machine Gun" and compare actions of SIA vs. Villar Perosa: They are similar

in MOST respects! For example, the SIA gun had a top-mounted magazine similar to that of

V.P. or Beretta Mod. 1918. Barrel was air-cooled and fixed to the receiver like barrel of

Villar Perosa.

Action and functioning of Villar Perosa Mod. 1915 were faithfully copied from

S.I.A. machine gun, designed before the First World War. Villar Perosa was designed for

use in aeroplanes as a flexible observer's gun (that's why the high rate of fire), but 9

mm Glisenti cartridge was not powerful enough for intended purpose. Aeroplanes were no

more frail "hand-looms" in the later part of First World War. They shot also

back with synchronized machine guns, loaded with explosive, incendiary and

armor-penetrating bullets. Especially Austrians preferred explosive projectiles in

dog-fights against Italian planes. V Ps were issued for ground use with bipods, but they

were not as comfortable in use as the later conventional or "real" submachine

guns with a butt-stock.

There was a cam slot on the side of tubular receiver. It's sloped rear surface twisted the

breech-bolt upwards during bolt's preliminary movement rearwards after a shot. Rear end of

the breech-bolt delayed opening by it's curved surface leaning on the cam of a striker

head, which was loaded by a recoil spring. (Delay cam arrangement between moving parts was

similar to the cocking curve in bolt-action rifles of Mauser-origin). The striker head

reciprocated in the receiver without twisting movement, of course. Delay of the

breech-bolt based partially on the friction ("Blish Effect") but mainly on the

velocity difference of moving parts and inertia of a rather heavy striker head.

Breech-bolt was still heavier, acting as a bolt of the conventional submachine gun.

Torsional inertia of rotating breech-bolt was, as such, presumably more important

retarding element than the friction between cam surfaces. I don't agree with Ian V. Hogg

that "there were several other and better designs available in 1920s". Agnelli's

SIA machine gun was an ingenious innovation despite of it's simple construction or,

actually, BECAUSE of it's plain design and absence of too many frail tiny parts.

"Simplicity is beauty for the eyes of a simple-minded spectator" (like me).

Action of Villar Perosa: Breech-bolt's delay lug (11)

reciprocated in the slot (12) of receiver. Slanted edge (13) of the cam slot twisted the

breech-bolt (10) downwards before a shot. Firing pin (14) could now hit on cartridge's

primer. After ignition of cartridge and a phase of peak pressure, the lug (11) was forced

to climb upwards/backwards from the cam slot, twisting the breech-bolt. Lug (15) of the

firing pin's rear end reciprocated in slot (12) without twist. Cam surface of

breech-bolt's rear end and slanted front edge of lug (15, pushed forwards by the recoil

spring) resisted twisting movement of a bolt (10) and delayed it's admission to the narrow

receiver slot (12) until the chamber pressure was dropped to safe level.

Residual pressure of powder gas pushed now the empty cartridge case and breech-bolt

backwards, compressing the recoil spring (16). Nail-like resilient spring steel ejector

(21) turned the spent case away from grip of the extractor hook (23) and tossed it

downwards out from receiver. When the next cartridge was fed into chamber from a

top-mounted magazine, the slanted cam surface of a lug (15, leaning on the curved surface

of breech-bolt's rear end) prevented strike of the firing pin to the primer of a

cartridge, until the breech-bolt was rotated 15 degrees of angle to clock-wise direction.

Bolt was still moving forwards, producing a "floating fire" just like a bolt of

submachine gun with a fixed firing pin.

(Source of drawing: Robert Kenneth Wilson, 1934. Captive written by P.T.K.).

It is often claimed that excessive cyclic firing rate of V P (up to 2000 rpm from single

gun) was caused by too light weight of a breech-bolt and insufficient design of

retardation. This theory is "hugaa" (= "bullshit")! Reason of high

firing rate was a very short reciprocating travel of breech-bolt (40 mm or slightly more).

Almost any selfloading pistol with blowback action is able to shoot 1500 - 2000 rounds per

minute if the firing mechanism is modified to give reliable burst-fire. Bolt travel of

SUOMI KP/-31 submachine gun is 80 mm (twice as long as that of V P). It's firing rate is

800 - 1000 rpm (depends on function, condition or absence of a vacuum valve in the

receiver end-cap). Some submachine guns with 120 - 150 mm bolt travel are able to generate

cyclic rate mere 350 - 500 rounds per minute, depending on bolt weight and stiffness of a

recoil spring. A rule of thumb is that doubled bolt travel shall divide the cyclic rate in

half.

I presume that You can find information about S.I.A. machine gun from Italy easier than I

can get it in remote Finland. SIA gun is, however, almost unknown everywhere nowadays.

Pictures and technical data are welcome to us if You are able to find some information

with a new consciousness about this subject of research. Sectional drawings are especially

wanted to our archives.

APPENDIX: Adoptment of the fluted chamber until 1960's.

Pre-1914: Giovanni Agnelli, Italy. S.I.A. machine gun.

Ca. 1930: Boris G. Shpitalniy & Komarichky, Soviet-Russia.

ShKAS rapid-firing aircraft machine gun.

Ca. 1939: Fyodor V. Tokarev, Soviet-Russia. Self-loading rifle SVT 40. (Just the case-neck

space of chamber is fluted).

1944 -45: Illenberger, Jungermann, Staehle & Vorgrimler, Germany. Last assault rifle

prototypes Mauser "Geraet 06 H" (without a gas-piston action) and assault rifle

"StG 45 (M)".

Ca. 1948: Ludwig Vorgrimler, Spain. (Formerly in France since 1945 until ca. 1947). CETME

assault rifle.

Ca. 1950: Ludwig Vorgrimler, France. AAT 52 machine gun. (Delayed blowback action was a

pre-WW II design of Hungarian Pál Kiraly. Also adopted to FAMAS assault rifle).

Ca. 1956: Schweizerische Industrie Gesellschaft/ Neuhausen, Switzerland. S.I.G. - SG 57

assault rifle.

Ca. 1958: Heckler & Koch GmbH, West-Germany. Modification of CETME rifle (G3). Since

1959 until today: Many pistols, rifles, machine guns, submachine guns and machine cannon.

Nota Bene: List may be incomplete since 1950. All the years of adoptment

are approximate, as just G. Agnelli patented a fluted chamber. Ansaldo, Armstrong &

Co. was presumably a "nominal patentee", which let the patent to drop in early

1920s or discontinued it's business entirely.

2305 MMI; PT

Swedish import of Bergmann and Suomi submachine

guns

In The Q & A Section below you wrote: "For international sales were

sub-variations of BMK 32 chambered for cartridges 7.63 x 25 mm Mauser, 7.65 x 21 mm Luger,

9 x 25 mm Mauser Export and 9 x 23 mm Bergmann-Bayard (a.k.a. 9 mm Largo in Spain). Sweden

bought in 1939 unknown quantity of Bergmann MP 35s, chambered for 9 x 19 mm Luger

cartridge, which was already a contemporary standard caliber of MP 35".

The quantity of Bergmann SMG/ MP 35 (Kpist m/39) in Swedish use was 1 800. One of

these sources is: http://www.mtek.chalmers.se/~m95perm/vapen/eldhandv/kpist.html#kpist_m39

. I have seen the same number twice in print so I think it is accurate.

I also have one question regarding Tikkakoskis export to Sweden. Do you have information

regarding delivieries per month or per Year? I have quite firm evidence that 800 m/37

where delivered before 31/12 1939. Thereafter Finland exported 900 m/37 and 350 m/37-39.

See http://www.mtek.chalmers.se/~m95perm/vapen/eldhandv/kpist.html#kpist_m37

.

Cheers; John, Stockholm, Sweden

Many

thanks for the information! Export/import statistics of German and Finnish submachine guns

seems to be correct, because Sweden could product licensed copies of SUOMI KP/-31 and

became soon self-supporting. Most (if not all) those 1800 "MP 35 Bgm"/

"Kpist m/39" submachine guns exported to Sweden were made by the Waffenfabrik

Carl Walther in Zella Mehlis or Zella St. Blazil, Germany. Records of Walther's Zella

plants became lost in the last phase of Second World War, but they may still exist in some

Russian archives, if not destructed.

I haven't literature about delivery of Suomi submachine guns to Sweden in my possession or

easily available.

1505 MMI; PT

Please wait, Honey! Gunwriters

updated! (c) Feliks

Dragunov rifle

I'm very impressioned about your weaponry's knowledge. Well, I want to buy a Dragunov

Sniper Rifle, but I wonder if I'll have a trouble with calibers and cartridges. Is it

possible to get this rifle in other caliber different to 7,62 x 54R? Where? Prefereably, I

wish some information about Scandinavian or Eastern European countries wich made it.

Many thanks, Pablo; Spain

I have

not up-to-dated knowledge about availability of Dragunovs chambered for other calibers

than 7.62 x 54R Mosin-Nagant. There was a civilian version with a rigid machined action

about similar to that of Dragunov SVD, known as Medved (Russ. "The Bear")

hunting rifle, chambered for 9.3 x 53R Russian cartridge, rarely met outside contemporary

Soviet Union. As far as I know, Finnish 9.3 x 53R Sako cartridge was impossible to shoot

from a Medved rifle, because of excessive overall length of Finnish 9.3 mm cartridge. 9.3

mm Russian had a bullet considerably shorter than that of 9.3 mm Finnish ammo.

In Finland we have no problems with Dragunovs (bought from Russia and ex-DDR for Finnish

army), because 7.62 mm Mosin-Nagant is a standard Finnish military caliber. Two

manufacturers are loading cartridges with a choice of bullets. The special sniping

cartridges (especially designed for SVD) are also bought from Russia for army. Years ago

there were imported Russian ammo with old-fashioned bullets, presumably pointed balls with

a weight 9.6 grams. They gave a poor accuracy from Dragunov, which was almost doomed as

"praised to the skies, but actually unfit for sniping".

Error was corrected later, when Russians told that SVD needs a high-quality projectile if

the best accuracy is needed. Some Finnish projectiles are also able to give a good sniping

accuracy. I don't know, whether Finnish 7.62 mm Mosin ("long rimmed Russian")

cartridges are exported to Spain. Those made by Lapua, with bullet D-47, weight 11 grams,

are good for SVD.

I have not knowledge about production of original Dragunov elsewhere but in Russia, even

in Eastern Europe. In Scandinavian countries they are never built. Finnish Valmet M83 LB

was not a copy of SVD, but a civilian variation of a light machine gun. A notorious

"Romanian Dragunov" (so called by a Finnish importer) looks like SVD, but it is

just with a narrow margin suitable for moose hunting to ranges less than 100 meters.

Dispersion of the groups may be more than 150 mm at a hundred meters range. Definitely it

is NOT a sniping rifle, because of it's flexible (flabby!) sheet-steel receiver.

You must try to acquire an original Soviet or Russian Dragunov rifle and 7.62 mm Mosin

cartridges for it. If the rifles or cartridges are unavailable in Spain, you must be

satisfied with some .308 Winchester bolt-action sniping rifle. ("Save Errors &

Omissions": I am mainly a firearms historician with always out-dated knowledge about

availability of modern COMMERCIAL weaponry).

1605 MMI; PT

SWOS - Silent Without Silencer. (c) Feliks

Pistol suppressor

Hi Pete. I've found the information you have provided on Gunwriters to be most

invaluable. You truly know what you are talking about which is a welcome change. I've

noticed that you have some information on suppressors, mainly for long arms and for .22

rim fire. I was wondering if you could please let me know if there was a way to suppress a

.38 with a 2 inch barrel. I know that this is probably a near impossible task but any help

would be greatly appreciated.

Thank you in advance,

Geoff

If the

.38 is a revolver, there is no easy way to suppress it. I don't think that it is sensible

to acquire a suppressor for a wheelgun. The blast of powder gasses leaking through a gap

between barrel and cylinder is about as noisy as the muzzle blast. Snub-nosed revolver

needs also long or thick suppressor. During the Second World War the Britons designed an

improvized method for suppression of revolver's gap blast, so called Churchill's

Mitten, a piece of car tyre's inner tube wrapped around the revolver (usually Enfield

with caliber .38/ 200) and hand & wrist of the shooter.

There was not a suppressor mounted on revolver muzzle but this rubber "mitten"

was able to suppress the muzzle blast too. Hand of the shooter became sooty and slightly

charred. Shots were not aimed but just pointed. Hits were possible to shoot at very short

range. "Churhill's Mittens" were never popular among the British warriors or

agents. They were issued until design of Welrod Hand Firing Devices and

suppressed Sleeve Guns. Not many books about WW II agent weaponry and special

devices have mentioned these makeshift revolver suppressors.

Finnish rangers knew also similar method for suppression of their .25 ACP caliber back-up

pistols, when they were sleeping during their trips behind Russian fighting lines. They

kept their pistols in shooting hand, covered with leather mitten. Beneath it was a wool

glove with two finger-stalls, one for a thumb and another for index/trigger finger.

Suppression of blast was not, however, a principal reason to keep a little pocket-pistol

in the hand covered with mitten, but need to open the fire immediately after moving the

safety to "fire" position. Hidden handguns were presumably never shot in anger,

but the rangers were trained to use them. Blasts of them were "somewhat muffled"

but shooting was unpleasant experience, because hot cases could drop into sleeve and burn

the wrist of shooter.

Swiss (?) suppressor expert Siegfried Huebner designed (or at least introduced) a

suppressed revolver with a sheet metal suppressor which covered barrel and cylinder of the

wheelgun. There is not a cut-away drawing of this .38 Special Smith & Wesson revolver

published, but S. Huebner told that "this revolver silencer really works".

Suppressor looks like a snug-fitting metal holster on the revolver, with rear and front

sights mounted on the suppressor. Aim is possible, but it is necessary to remove the

revolver from it's "holster" for swinging the cylinder open, removing the cases

and loading the chambers. As far as I know, this kind of revolver suppressor was unique

sample, too difficult to mass-produce.

If your .38 caliber gun is not a revolver but truly a pistol, give the more detailed

information about it, please!

1305 MMI; PT

Gunwriters - Fastest of it's kind!

(c) Feliks

Factory-loads vs. handloads

Dear Pete, I cannot seem to duplicate Remington Express Rifle Ammunition ballistics with

handloads. The 140 grain PSP Core-Lokt average 3517 across chronograph. The best I can do

with any powder is 3156. My rifle is a Remington 700 Sendero 26 inch stainless steel

fluted barrel. I have tried almost every powder listed in my manuals.

Thanks, Eric

Powder

of factory-loaded ammo may be unavailable to handloaders or your bullets may be different

from those produced for factory-loads. 3156 feet per second for 140-grains 7 mm Pointed

Soft Point bullet is a sufficient velocity. Do not try to duplicate ballistics of factory

load with excessive powder charges. They'll shorten the life of your rifle barrel and

especially the cartridge cases.

On the manuals are Maximum Loads usually somewhat less than the charges of factory loads,

because cartridge manufacturers does not like the idea that the case of once-shot

cartridge is able to stand too many reloads and shots. Reloading data on manuals is

published by "better safe than sorry"-principle, considering also active life of

gun barrels and cartridge cases.

My old Hodgdon Data Manual No. 26 (compiled in 1987) give just one 7 mm Remington Express

load generating 3000+ fps velocity for bullets with weight 139-140 grains: 55 grains of

powder IMR 4831, generating velocity 3009 fps and 51 000 C.U. Pressure (Maximum Load!).

Test-barrel length has been 24 inches. Your stainless 26" barrel is able to generate

about 150 fps extra velocity with this 55 grs charge of IMR 4831, but definitely not 3517

feet per second. I don't know, whether Remington loads their cartridges with Finnish

VihtaVuori N550 or N560 powder, because there is no loading data for 7 mm Rem. Express

published in Finland at all.

1305 MMI; PT

Gunwriters - Danger! Informative!

(c) Feliks

Box still open for contributions?

Greetings, wonderful job you are doing out there in Finland! I am inquiring if you still

maintain the PO Box for CA$H contributions, and if so I would like to donate a picture of

dead president to you. Please let me know how to go about doing this?

"Gun Control means you can hit your target!"

Cliff.

Lease

contract of our PO Box is still valid until 1st June 2001 and I'm planning to renew it

since day of expiring until 1st June 2002. CA$H contributions are easy and sure way to

keep GOW/Universal alive. PO Box is also essential for receipt of letters, drawings,

diskettes, ROM-CDs, catalogues, books and other mail. (My street address is horribly long

with two Scandinavian letters "ae"). I have not direct contact to the Web,

presumably needed for contact with currency transfer system "Pay-Pal"

mentioned on some messages from our US visitors. It is not yet known to me, whether

Pay-Pal system extends to Finland. Therefore the pictures of late US presidents or finance

minister Andrew Hamilton are welcome donations.

An usual letter is safe and sure way to send them over here. Our address shall remain

unaltered:

GOW, P.O. BOX 525, 80161 JOENSUU, FINLAND, EUROPE

Many thanks in advance, 0505 MMI; PT

PS. Finnish submachine gun KP-44 is among the easiest guns to control... (By the gunner,

of course!).

.375 WINCHESTER BIG BORE RELOADS

MY NAME IS MAR AND I AM WRITING TO YOU FROM SPAIN BECAUSE I HAVE A PROBLEM WITH MY RIFLE'S

ANMUNITION. I HAVE A WINCHESTER .375 BIG BORE. THIS MODEL IS UNKNOW IN SPAIN. ONLY TEN

RIFLES WERE EXPORTED TO SPAIN SINCE 1979 UNTIL 1987.

IN FEBRUARY OF THIS YEAR I FINISHED THE .375 BIG BORE 250 GRAIN POWERPOINT AND MY ARMORER

CAN FOUND ONLY WINCHESTER .375 SUPER X CARTRIDGES WITH 200 GRAIN PP CXP2 BULLETS (FOR

ELK). HE SAYS THAT CXP3 AND CXP4 ARE NO MORE MADE OR THEY DON'T ARRIVES TO SPAIN.

1- IS THIS AMMUNITION THE SAME AS THE OLD .375 BIG BORE CARTRIDGE? SOMETIMES I THINK TO

RELOAD CARTRIDGES BUT ANYBODY HERE KNOWS CERTAINLY WHAT CHARGE IS GOOD AND HOW MANY GRAINS

ARE THE MAXIMUN RECOMMENDED.

2- CAN YOU EXPLAIN IT MORE?

3- WITH HOW MANY GRAINS BULLETS IT IS SAFE TO HUNT IN AFRICA (CAPE BUFFALO OR ELEPHANT)?

4- THE NEW WINCHESTER SUPER X .375 200 GRAINS, ARE THEY GOOD TO ACCEPT MORE GRAINS OF

POWDER IN THE RELOADS?

5- WHAT DO YOU THINK ABOUT WINCHESTER .375 BIG BORE 94?

THANK YOU VERY MUCH AND PARDON FOR MY BAD ENGLISH.

SINCERELY; M. D. L. T., SPAIN.

Don't worry

about your English which was not too bad. I'll always do some editing if needed.

1- There were or are two different .375 caliber cartridges for variations of Winchester

1894 rifles, namely old .38-55 Winchester & Ballard and .375 Winchester (Big Bore) for

1894 Angle Eject rifle. Last rifles chambered for old .38-55 cartridges were made in 1940.

Your rifle is so an Angle Eject 94 variation and caliber is .375 Winchester. Case of old

cartridge .38-55 is too long and fat for .375 Win. chamber. Don't use it for reloading.

Save the cases with headstamps .375 W. for your reloads. Our problem is ignorance of

powders easily available in Spain. One of our Spanish visitor has told that there are no

powders available for reloaders but he is fortunate enough to live close to French border.

He is therefore able to acquire powders from France where a large choice of them is for

sale.

2- Winchester Angle Eject 1894 rifle has considerably stronger action than original model

1894 and although the case of .375 Win Big Bore cartridge is shorter and slimmer than the

shell of old .38-55 W & B and it's volume is considerably reduced because of increased

wall and head thickness, the .375 Win. cartridge is able to generate considerably higher

bullet energy than .38-55 ammo, but of course with accordingly higher chamber pressure.

3- For African big game is needed a deeply penetrating bullet. Suitable projectiles have a

round or sharp point, strong full-metal jacket construction, unless the bullet is not a

solid projectile of some copper alloy or pure copper. Preferable weight is 300 grains or

more. I afraid, there are no bullets available for .375 Winchester cartridge suitable for

elephant or African buffalo hunting. Easily expanding flat-nosed soft point bullets are

good for deer, elk and marginally for moose hunting. Especially the pointed FMJ bullet is

risky in a rifle with a tubular magazine unless the cartridges (or at least first one) are

fed manually to the chamber.

4- When the cartridge is loaded with Winchester 748 powder, the suggested starting loads

are 42 grains for 200 gr bullet, 40 grs for 220-grainer bullet and 38 grs for 250 gr

projectile. Maximum load of W 748 powder for 250-grainer bullet is 40 grains, generating

muzzle velocity 555 meters per second and for 200 gr bullet the maximum charge is 44

grains, generating muzzle velocity 611 meters per second. You may load cartridges with 200

grains bullet with ca. 10 % heavier powder charges, when compared to 250 grains bullet and

gain accordingly higher bullet velocity at moderate ranges. For extended ranges the

heavier bullet is preferable, because the air resistance shall reduce velocity of

200-grainer projectile sooner than velocity of heavier bullet. Rifling twist of your rifle

is able to stabilize also flatpointed 255 gr bullets.

Please Note: Before you'll start reloading, tell to us producers, names or numbers of the

powders and bullets available in Spain. We are able to calculate safe reloading

combination for your rifle.

5- The .375 Winchester 1894 Big Bore/ Angle Eject rifle is an obsolete model. Curtailed

choice of factory-loaded cartridges is sign of a "flop". Nine years after

introduction of .375 Winchester rifle and cartridge there were comments published on

HODGDON DATA MANUAL No. 26: "As this is written in late 1987, no rifle is available

in .375 Winchester, and Winchester has discontinued the 250-grain factory load".

It is advisable to buy all the cartridges you can get and save the cases. You can get very

soon cartridges by reloading only! Fortunately enough, the .375 caliber flat-nosed bullets

are still available, but my philosophy has always been: "Avoid all firearms with

non-military centerfire caliber! Civilian cartridges are coming and going while many old

military cartridges (like 7.62 mm Mosin-Nagant and still older .45-70 Government) are

strongly alive and brisk".

1005 MMI; PT

Mysterious "TIKKA" stamp on Bergmann MP

34.I

Thank you very much for your detailed reply to my question. As I

look at what I sent to you, it looks as if I failed to attach the photo of the marking. If

you get time, would you please look at the picture I am sending and verify that it is a

Tikka mark? Is the T inside the triangle oriented correctly? Soviet Tula arsenal may have

used a similar stamp.

Again, thanks very much,

Byron, New Mexico, USA

During

1930s the stamp of Tulskiy Orucheiniy Zavod was "T" in a five-pointed

star or cyrillic letters "TO3". Stamp of Ischyevskiy Orucheiniy

Zavod was a triangle with a fledged and barbed arrow, pointing upwards inside the

triangle. Apex of "Tikka" triangle is downwards; that of Ischevskiy

stamp shows upwards. Stamp on your submachine gun is definitely a "Tikka" stamp.

0905 MMI; PT

IMPORTANT SUPPLEMENT: Predecessors of Bergmann-MP 35

I have found some additional information about early variations of "MP 35 Bmg" submachine guns from a reliable German

source. The first model was known as "BMK 32". Guns were made by a famous

sporting/hunting rifle manufacture SCHULZ & LARSEN in Otterup, Denmark. Transitional

variations were known as "MP 34 Bgm" and "MP 34.1 Bgm". They were made

in Denmark and Germany. Germans were bold enough to use abbreviation MP already in 1934, a

year after fall of the degenerated Weimar Republic's administration. Model "MP

34.1" existed but "MP 35.1" didn't.

Supplementary information about making of pre-MP 35 in Denmark is giving support to my

view that there is at least one sample gun made in Finland by TIKKAKOSKI Oy,

which had experience on manufacturing of submachine guns. "BMK 32" and "MP

34 Bgm" guns made by Schulz & Larsen were presumably made with tool-shop

machinery, being expensive. It was, however, possible to produce unlimited quantities of

submachine guns again in Germany, which was separated from League of Nations in

14th October 1933 and started re-armament. Production of "MP 34.1 Bgm" returned

from exile back to it's roots, to the rising Deutsches Reich. It was no more needed to

search foreign manufacturers.

General conscription was declared in 1935, but "MP 35 Bgm" became never a

standard submachine gun of German Wehrmacht. Those guns produced were issued to SS and

some other special troops. They were not very popular, because of old-fashioned horizontal

magazine extended to right side of the receiver. Empty cases were ejected to left side of

a gun. When shot from prone position, the hot shells could bounce towards face of the

gunner. Left-handed gunners were happy: It is said that designer of BMK 32 (Hugo

Schmeisser) was a "southpaw", just like Samuel Colt.

All the variations altogether, no more than 40 000 guns were made, most of them in

Germany, small batches in Denmark and presumably just one gun in Finland. Unfortunately

this last assumption seems to be impossible to confirm from available literature or

information from Tikkakoski Oy, which has been out from firearms business since mid-1980s.

Many records of Tikkakoski were destructed before the firm became property of Soviet Union

after our 3rd Independence Struggle.

For international sales were sub-variations of BMK 32 chambered for cartridges 7.63 x 25

mm Mauser, 7.65 x 21 mm Luger, 9 x 25 mm Mauser Export and 9 x 23 mm Bergmann-Bayard

(a.k.a. 9 mm Largo in Spain). Sweden bought in 1939 unknown quantity of Bergmann MP 35s,

chambered for 9 x 19 mm Luger cartridge, which was already a contemporary standard caliber

of MP 35.

0605 MMI; PT

ADVERTISEMENT

We are very glad to announce you the issue of our most recent E-book.

The DWM Lugers.

Download address : http://users.skynet.be/HL-Editions/ebook/eluger2.htm

Content of our E-book

The firm DWM - A brief history - The firm LOEWE und Cie - The Deutsche

Metallpatronenfabrik (DM) - The Deutsche Waffen- und Munitionsfabriken AG (DWM) - The

Berlin-Karlsruher Industrie-Werke (BKIW) - The Industrie-Werke Karlsruhe (IWK) - Hugo

BORCHARDT - Georg LUGER

The evolution of the Borchardt pistol - The Borchardt pistol - The Borchardt hold-open

device improvement - The Borchardt improved model of 1909 - The mysteries about the 1909

model - A patent for a trigger mechanism

From the Borchardt to the Luger pistol - The roots of the story - DWM requested that Luger

undertake the redesign - The chronology of Georg Luger earliest involvement - The

transitional models until the 1898 model

Luger's patents and the issue of fakes - The list of the German patents granted to Georg