To Link

Page To Gunwriters' Index Page To Part 2/2 of Suomi History

MOWING MACHINE OF TIKKAKOSKI:

Muzzle brakes or

compensators are useless gimmicks on long-barreled submachine guns like KP/-31. Pressure

of the muzzle blast is too low to generate reaction force strong enough to prevent

"muzzle climb". A skilful submachine gunner can easily control the recoil

and keep the gun steady, by keeping the thumb of his trigger hand behind the breech-cap.

This thumb must receive whole recoil force. The butt of the gun is not allowed to hit or

even touch shoulder of the gunner. Another way to control the recoil is to keep the gun

with stiff hands, again without solid contact on the shoulder.

Muzzle brakes or

compensators are useless gimmicks on long-barreled submachine guns like KP/-31. Pressure

of the muzzle blast is too low to generate reaction force strong enough to prevent

"muzzle climb". A skilful submachine gunner can easily control the recoil

and keep the gun steady, by keeping the thumb of his trigger hand behind the breech-cap.

This thumb must receive whole recoil force. The butt of the gun is not allowed to hit or

even touch shoulder of the gunner. Another way to control the recoil is to keep the gun

with stiff hands, again without solid contact on the shoulder.

Suomi Submachine Gun, KP/-31

Part 1/2

Text: P. T. Kekkonen

Photographs: J. Hartikka

Proofreading: Eero Juhola (See home pages: Finnish Weapons)

The famous Suomi submachine gun or machine carbine was designed to be an

"everlasting" piece of equipment. Broken or worn-out parts like extractors,

barrels, breech-bolts, recoil springs and wooden stocks were easy to replace. Receiver and

jacket were truly durable parts, and - with the exception of some springs and pins - the

small pieces of trigger mechanism did not easily wear out. The very first prototype of the

SUOMI gun was made by a young Finnish Army armorer, AIMO JOHANNES LAHTI (1896-1970) in

1920 or 1921. The caliber was .32 A.C.P. or 7.65 mm Browning. The gun was 30 centimeters

(11.8 inches) long. This "machine pistol" was a very reliable gun but the .32

Auto cartridge was too weak for "serious military use" and the cyclic rate of

fire was presumably too high.

It is not known, whether designer Lahti attempted to remedy this fault of all "rattle

pistols" with some kind of pneumatic firing-rate reducer. Prototype gun and it's

drawings are, unfortunately, lost forever. Next prototype Suomi, in caliber 7.65 x 21 mm

Parabellum or Luger, was made by machine and tool manufacture Engineering Shop Leskinen

& Kari, of Tampere, Finland, in 1922. A single specimen of Konepistooli (machine

pistol) model 1922 survives in a German museum, the Wehrtechnische Studiensammlung in

Koblenz.

The first Finnish patent on submachine gun was applied and granted in 1922. The inventors

were Master Armorer A. Lahti, lieutenant Y.Koskinen and L. Boyer-Spoof, also lieutenant of

Finnish Army and the commanding officer of Aimo J. Lahti.The patent was granted on

September 11, 1922 and covered a new way to attach the barrel, and the trigger mechanism

with a simple selector for semi-automatic shooting. The breech bolt of the early model

M/22 was similar to those of the German Bergmann, the British STEN and the Australian Owen

bolt, but there were some special design features to reduce otherwise excessive cyclic

rate of fire since model M/22. The firing-rate reduction devices were based on air

compression or vacuum behind the breech-bolt, which was almost hermetically fitted to the

tubular receiver.

According to the patent drawings most of the devices were too delicate and difficult to

adjust correctly. The least complicated firing-rate reducer device, a simple vacuum valve,

was used in every Suomi submachine gun since 1930 to ca. 1986, when last examples of this

magnificent piece of equipment were assembled. Designers of "Pre-Suomi", A.

Lahti, Y. Koskinen, L. Boyer-Spoof and their commanding officer captain V. Korpela, formed

a company "Konepistooli Oy" ("Machine Pistol Ltd.") for submachine gun

production.

The company Leskinen & Kari was able to make just a tiny batch of prototype guns (less

than five handmade pieces) but tool-making Shop Tool Oy, in Helsinki, could make all the

necessary equipment for production of machine pistols. A large industry hall was shared

with another machine and toolmaking shop, Leonard Lindelöf Oy, which also made submachine

guns, licensed copies of German Bergmann MP 18-1 from 1923 until 1932. During this time

Lindelöf Oy could assemble only sixty (more or less miserable) copies of the MP 18, while

Tool Oy made more than a hundred guns in the first years of manufacturing, from 1922 to

1925.

The barrels of these "pre-Suomi" models were bought from England. All other

parts, except the Swiss-made recoil springs from the Bergmann MP 18-1, were made in

Finland. Almost all essentials of the Suomi gun were present in Konepistooli Osakeyhtiö's

model KP/-26. The front of the breech-bolt was rebated, or "necked", just like

in Villar-Perosa and Thompson submachine guns, to assure a reliable feed. The cocking knob

was non-reciprocating. Rear end of the receiver was almost hermetically sealed and its end

cap enclosed a screw-adjustable firing rate reduction device which worked by vacuum.

From "pre-Suomi" to KP/-31

An adjustment of the cyclic rate was necessary because of readiness to adopt caliber 7.63

x 25 mm Mauser for export model submachine guns. The length of the breech-bolt stroke was

just a bit more than the overall length of 7.63 mm Mauser or 9 x 25 mm Mauser

"Export" cartridge. The Finnish Army, Frontier Guards and Civil Guard were

satisfied with the less powerful but very accurate 7.65 x 21 mm Parabellum cartridge,

which had been an official pistol caliber of armed forces since 1923.

The magazine of the "pre-Suomi" guns was a curved box, for 36 rounds, going

through a rather narrow magazine-well into the receiver. It was impossible to develop a

well-designed large drum magazine for gun like KP/26. Russians learned this fact the hard

way - the Finns with less difficulty.

The designer Aimo J. Lahti honed his invention to perfection during years 1930 - 1931. His

intention was to sell the manufacturing rights of this Suomi submachine gun to the State

of Finland, but the Finnish government had no manufacturing capacity in state-owned

Valtion Kivääritehdas (VKT. Since 1946 VMT. Since 1950 until 1988 Valmet Oy/ Tourula

Works).

The privately-owned Iron and Wood Industry of Tikkakoski, or since 1929 just Tikkakoski

Oy, bought the manufacturing license of the greatly improved submachine gun, now called as

Suomi-KP Model 1931. The owner of the license for submachine gun manufacture was, of

course, the patentee of several improvements on KP Model -26, which altered the

"pre-Suomi" gun into the real Suomi gun.

The patent application, dated July 4, 1930, covered a "full-automatic firearm with a

blow-back bolt and a vacuum valve in breech-cap". Another patent application, dated

July 5, covered an oblique front face of barrel jacket as compensator of

"jump-effect", and a combined full-auto, semi-auto and safety selector placed

ahead of the trigger. A third patent, also applied for July 5, covered barrel jacket

bayonet-mounting and an improved, positively locking bolt.

A section drawing of the Suomi KP/-31 submachine gun. An original illustration from the booklet "SUOMI-KONEPISTOOLI" by OY TIKKAKOSKI AB (in 1942). Click image to expand for closer look.

Remarkable Innovations

Some unpatented but significant improvements were the adoption of 9 x 19 mm Parabellum or

Luger cartridge and an "open-jaw" magazine well, which allows the use of drum

magazines along with a Swedish pattern double staggered-row magazine or "a coffin

clip", as well as the usual staggered-row clip for 20 rounds.

The new owner of the manufacturing license, Tikkakoski Oy, was actually a multinational

enterprise. The main stockholder was a German called Willi Daugs. The first shots

discharged in anger were fired during the Gran Chaco War between Bolivia and Paraquay in

1932 to 1935. Apparently both belligerents possessed some Suomi submachine guns, either

imported from Finland or captured. South America, the Baltic countries and Poland were

objects of exporting effort before, and Sweden, Bulgaria, Denmark, Germany, Croatia and

Switzerland during World War II. Manufacturing licenses were sold to Denmark, Sweden and

Switzerland.

Lessons for whole World

Most Finnish-made guns were, however, bought for use

by the Finnish armed forces. When the Russians tried to incorporate Finland into "the

Big Happy Family of Soviet Nations" in November 1939, there were about four thousand

submachine guns model KP/-31 ready for a hot salutation against unwanted liberators. This

famous Winter War taught whole world to value of submachine guns as true instruments of

warfare, not mere "emergency weapons for defense at close quarters for the personnel

of specialist corps, such as motor transport drivers, spare numbers of machine-gun units,

tank crews and head-quarter details." (Quotation from a British "Textbook of

Automatic Pistols" by Robert Kenneth Wilson, written in 1935).

Most Finnish-made guns were, however, bought for use

by the Finnish armed forces. When the Russians tried to incorporate Finland into "the

Big Happy Family of Soviet Nations" in November 1939, there were about four thousand

submachine guns model KP/-31 ready for a hot salutation against unwanted liberators. This

famous Winter War taught whole world to value of submachine guns as true instruments of

warfare, not mere "emergency weapons for defense at close quarters for the personnel

of specialist corps, such as motor transport drivers, spare numbers of machine-gun units,

tank crews and head-quarter details." (Quotation from a British "Textbook of

Automatic Pistols" by Robert Kenneth Wilson, written in 1935).

Shooting with sling and instinctive aim. Experienced

submachine gunners preferred this method during Finnish wars of 1939 - 1945. This

particular gun is equipped with a quadruple-row "coffin magazine" and has a

silver plaque on the right side. A nice birthday present to a Finnish firearms collector

from a distinguished ranger veteran of the 1941 - 44 war. Shootable? Of course..!

Construction of KP/-31

The words "robust" or "sturdy" capture the essence of the so called

"first generation submachine guns" such as Thompson, Bergmann and Suomi. They

were not yet spot-welded from sheet steel stampings and tubings, along with rough

investment-cast main parts and brittle phenolic plastic components (called by disparaging

name "gutta-percha parts" in Finland). The true Suomi, Konepistooli model 1931,

is entirely made in Finland.

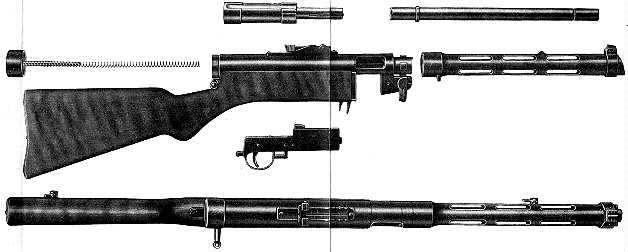

KP/-31 stripped to main parts. Photograph from original illustration of the booklet "SUOMI-KONEPISTOOLI" by OY TIKKAKOSKI AB (in 1942).

The Barrel

Barrels were initially made by Birmingham Small Arms in England but from 1930 onwards by

Tikkakoski Oy, or the Gunsmithing Shop Joonas Matarainen, in Finland. Especially J.

Matarainen drilled, rifled and lapped the bores of submachine guns with same

scrupulousness as those of his famous competition rifles. There were always two barrels

for each KP/-31, both of them selected to shoot with the same adjustment of sights. If one

or other barrel was worn-out by shooting or corroded by lack of proper maintenance, it was

easy to get more spare barrels from factory or depot by order.

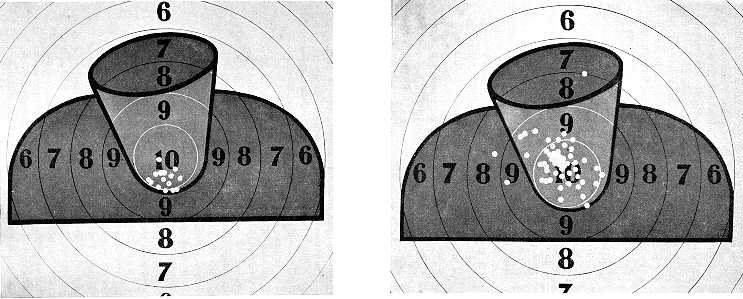

If the "sighting-in stamp" in the rear flange of barrel was matched that of the original barrel it was guaranteed that the center of hit-group (ten aimed shots at 100 meters) was within one inch (25 millimeters) of the aim-point, without re-adjustment of sights. Semi-automatic test shooting was conducted by factory test-shooters using just a simple bench rest. All ten shots must hit on the bullseye of the target at one hundred meters. Diameter of the bullseye was 100 millimeters, or less than four inches. Sub-M.O.A. groups weren't uncommon occurrences.

The KP/-31 was the accuracy standard to which other sub-machine guns of the time were compared. Above are two targets shot during official Army weapon acceptance tests from 100 meters' distance. Left target: 15 rounds of semi-auto shots from bench rest. Right target: 50 rounds of full auto shots as a single long burst from bench rest. Photograph from original illustration in the KP/-31 manual "SUOMI-KONEPISTOOLI" by OY TIKKAKOSKI AB (1942).

Milled from solid steel

The receiver is machined from solid steel forging, with accurately bored and honed

thru-going tunnel for the breech-bolt and a concentric, narrower tunnel for the rebated

"neck" of the bolt. The outside diameter of receiver is 37 millimeters and the

diameter of the breech-bolt is 31 millimeters, with practically air-tight fitting into

receiver. The rear end of the receiver is closed with a screw

cap. Its seven threads are not interrupted, like those of Bergmann MP 18-I or 28-II. When

field stripping and re-assembling the action of KP/-31, it is necessary to wind six to

seven rotations of the cap while keeping the recoil spring compressed by pulling the

cocking knob rearwards . The "hermetic" cap closure was found essential to

assure proper functioning of firing-rate reducer or vacuum valve within the cap.

The rear end of the receiver is closed with a screw

cap. Its seven threads are not interrupted, like those of Bergmann MP 18-I or 28-II. When

field stripping and re-assembling the action of KP/-31, it is necessary to wind six to

seven rotations of the cap while keeping the recoil spring compressed by pulling the

cocking knob rearwards . The "hermetic" cap closure was found essential to

assure proper functioning of firing-rate reducer or vacuum valve within the cap.

Start of field stripping. Pull the cocking knob all the way backwards and while holding it, unwind the breech-cap (seven rotations counter-clockwise). IMPORTANT NOTE: The powerful recoil spring is fully compressed during winding and unwinding breech-cap! Keep your thumb on the center of the cap while rotating it with fingers of another hand.

It is necessary to to remove barrel jacket and barrel for routine maintenance, inspection and bore cleaning. Contrary to Bergmann MP's (to say nothing about Thompson), it is easy to remove even a red-hot barrel and install a cool spare barrel into front end of the receiver; just turn the jacket-key 90 degrees downwards and rotate the jacket 45 degrees to left, then pull the jacket forwards and loosen the barrel, also forwards.

Breech-cap and recoil

spring removed. Note the rebated "bolt neck". KP/-31 is among the most reliable

automatic firearms if the cartridges are faultless, the magazines flawless and the

maintenance of mechanism is done scrupulously - without overdoing. As an example the

inside of the receiver is not be lubricated but washed "bone dry" with gasoline

or kerosene, especially in frosty weather, when the slightest amount of grease or oil may

cause misfire or even a more serious accident. Contrary to a common misconception,

shooting with an unlubricated gun does not cause wear of receiver or moving parts.

Breech-cap and recoil

spring removed. Note the rebated "bolt neck". KP/-31 is among the most reliable

automatic firearms if the cartridges are faultless, the magazines flawless and the

maintenance of mechanism is done scrupulously - without overdoing. As an example the

inside of the receiver is not be lubricated but washed "bone dry" with gasoline

or kerosene, especially in frosty weather, when the slightest amount of grease or oil may

cause misfire or even a more serious accident. Contrary to a common misconception,

shooting with an unlubricated gun does not cause wear of receiver or moving parts.

Q.D. Barrel Was Essential

During the war it was often necessary to cover hand with a mitten or thick cloth before

grasping the hot jacket, and to push the red-hot barrel out with the point of a

puukko-knife. The quickly detachable barrel, bayonet-mounted by four heavy lugs,  was a rather expensive technical construction but actual fighting

experience often proved it a successful barrel mounting method, compared with the thread

mount of Bergmann or STEN and the fixed barrel of the Thompson. Many Finnish submachine

gunners shot several thousand rounds during an hour or two, mowing down oncoming Russian

hordes during the Winter War and the Finnish Third Independence War of 1941 to 1944.

was a rather expensive technical construction but actual fighting

experience often proved it a successful barrel mounting method, compared with the thread

mount of Bergmann or STEN and the fixed barrel of the Thompson. Many Finnish submachine

gunners shot several thousand rounds during an hour or two, mowing down oncoming Russian

hordes during the Winter War and the Finnish Third Independence War of 1941 to 1944.

Removing a (cool) barrel and jacket is easy, compared with almost any submachine gun (save the OWEN). Turn the jacket latch or key down. Then, turn the jacket counter-clockwise while pulling it forwards. Once the jacket is removed, pull the barrel forwards out from the receiver.

Sometimes a single Finnish submachine gunner against a hundred Russians. At other times

one gunner and a couple of magazine-filling assistants struggled against a full infantry

company - 200 Russians - killing almost half of their troop and wounding many others. Some

Finnish writers of war and remembrance novels say they have given too small numbers of

Killed In Action enemy soldiers in their books because "nobody can believe my

eye-witness' claim that one submachine gunner can slaughter eighty-five enemy soldiers

during a skirmish lasting less than thirty minutes"..! Harsh facts are sometimes more

incredible than fictions of novel writers.

If the jacket and barrel are hot after shooting it is advisable to protect the hand. A thin handkerchief is insufficient for this purpose after a discharge of twenty shots on automatic. A bullet of faulty cartridge stuck in the bore was the usual reason for barrel replacement during battle. According to the booklet "SUOMI-KONEPISTOOLI", published in 1942 by O/Y TIKKAKOSKI AB, it was allowed and safe to remove a stuck bullet by shooting with a full-powered cartridge. This harsh method was, of course, "for extreme urgency only". The primer of cartridge usually exploded during shooting away the stuck bullet, and the extractor disappeared after "duplex ball" shot, but the KP/-31 works well with no extractor at all. The thick-walled barrel easily withstood this misuse but it was necessary to remove the magazine and push the cartridge manually into the chamber.

In combat it was not

unusual to shoot barrel and even the jacket of KP/-31 literally red-hot. If cleaning-rod

was not at hand it was possible to turn the jacket loose with the edge of a puukko-knife

and knock the barrel out with the point of puukko. Every Finnish fighter had (and still

has) a knife with sheath as a multi-purpose tool, always hanging on his or her belt.

In combat it was not

unusual to shoot barrel and even the jacket of KP/-31 literally red-hot. If cleaning-rod

was not at hand it was possible to turn the jacket loose with the edge of a puukko-knife

and knock the barrel out with the point of puukko. Every Finnish fighter had (and still

has) a knife with sheath as a multi-purpose tool, always hanging on his or her belt.

Bolt Chiming Like a Bell

The breech-bolt of the KP/-31 is as well made to be everlasting, as is the receiver of the

gun. It is also machined from the best Swedish chromium-nickel steel available in

Thirties and Forties, hardened to 55 Rockwell Cone Hardness, and ground between apices

(centers) of grinding machine. The firing pin is fixed but removable for replacement if

broken. (Point breaks are very rare accidents, despite of length and sharpness of the

firing pin point, necessity for reliable ignition of war-time priming caps). The firing

pin of "pre-Suomi" guns was somewhat similar to that of the Thompson submachine

gun, with a separate actuating lever and firing pin returning spring. In late 1920s Aimo

J. Lahti found this construction overly complicated and unnecessary.

The only Achillean heel of the bolt was the extractor hook which was made of spring steel

but, like most well-designed automatic firearms with blowback action, the KP/-31 is able

to eject spent cases without any extractor at all. It was just advisable to keep the gun

on its right side, ejection port downwards, but this "mowing-fire hold" was

natural to experienced gunners.

Firing Cycle

Preparations for shooting are as follows: Pull the cocking knob all the way rearwards

until the breech-bolt remains in the rear position. The firing mode selector must be

pushed to the frontmost (Full Auto) or intermediate (Semi-Auto) position. The selector's

rearmost position (Safe) prevents movement of sear, and firing and cocking of the KP/-31.

It is usually possible to push box magazines into the magazine-well of an uncocked

submachine gun, keeping the fire selector in "Safe" position until shooting. All

box magazine types may be attached by pushing in, upwards until an audible snap is heard.

Drum magazines are, however, only mounted into a cocked gun. The pull of the trigger lets

the breech-bolt to move forwards. The stroke length from triggering to discharge is 70

millimeters (2.76 in.). The recoil-spring actuated breech-bolt gains "momentum"

for slightly more than half of this distance. Then it picks a cartridge from magazine and

thrusts it into chamber.

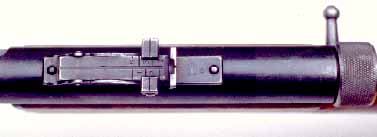

Top view of the receiver. The rear sight is graduated to 500 meters for harassment firing. Aimed shots could hit enemy individuals within 300 meters, but within distances of less than a hundred meters - common in skirmishes in afforrested terrain - the shooter simply pointed the gun in the direction of the enemy without aiming. Most skilled submachine gunners could operate their KP/-31 like a long-range shotgun, without the need of sights. A high rate of full-automatic fire had its uses.

"Differential Locking System"

The firing pin point, protruding 1.20 to 1.25 millimeters from the face of the flat

bolt-recess bottom, dents the bottom of the primer and discharges cartridge, while the

breech-bolt is still going forwards. The MOMENTUM of the bolt (MASS multiplied by

VELOCITY) keeps the cartridge case immobile in chamber, until the peak pressure of the

powder gases has lowered to ten per cent level from 2600 atmospheres (the allowable

maximum chamber pressure of the 9 x 19 mm Luger cartridge). During the pressure peak the

breech-bolt is still moving forwards, accomplishing the so called "differential

locking" by combined weight and velocity, momentum.

When the movement of the bolt has stopped, the walls of the cartridge-case stick into the

walls of the chamber, slowing down or temporarily stopping backwards movement of the bolt.

During this time the bullet comes out from the muzzle. Gas pressure in the bore and

chamber falls down rapidly. The elasticity of metal loosens cartridge-case from the

chamber walls. The remaining gas pressure blows the case backwards like a piston of an

internal combustion engine.

The spent case pushes the breech-bolt back against the power of the recoil spring and the

inertia of bolt weight. The mass of the bolt gains velocity (again the momentum) which

hurls the bolt back the whole cyclic stroke length of 82 millimeters, until the rear-end

of the bolt meets the diaphragm of the receiver end-cap. Firing now continues until the

last cartridge is spent, if the fire selector is pushed to the frontmost "Full

Auto" position. Release of the trigger stops the shooting. An expert submachine

gunner can shoot bursts of two or three shots despite the rather high cyclic rate of fire

- 750 to 800 rounds per minute with usual 9 mm pistol loads and up to 1000 r.p.m. with

Finnish, German or Canadian special 9 mm submachine gun loads.

Cartridges which are too weak may also develop a high cyclic rate, along with

uncontrollable fire: The release of trigger will not stop firing and the gun shoots a long

burst until the magazine is empty, even when fire selector is in "Semi-Auto"

position! If the gunner is inexperienced the consequences of uncontrollable fire become

fatal to bystanders! If the pressure of powder gas and/or the momentum of retreating

breech-bolt is insufficient to thrust the bolt backwards no more than ca. 60 to 69

millimeters the retreat of bolt too short. Then the sear cannot catch the bolt but the

bolt is by now able to eject the spent case and pick the next cartridge from the magazine,

thrust it into chamber and discharge it. This phenomenon, known as a "short

stroke", is well-known to designers of special handloads (especially subsonics), but

some weakened wartime surplus cartridges may also develop short strokes.

Submachine Gun as a Small-Game Rifle

The trigger mechanism has no positive disconnector, like as that of the STEN or Bergmann MP 28-II, but if the original or spare bolt is fitted with

skill and knowledge it is possible to shoot single shots with the KP/-31, one per a pull

of the trigger at a rate of twenty to thirty aimed shots per minute - depends on

the skill and experience of the gunner. During the Third Finnish Independence War (or the

Russian Great Patriotic War - your choice) the KP/-31 was used as a hunting rifle in order

to acquire some more meat in the form of forest birds and squirrels, thus making the

diluted war-time soup more nutritive. An experienced hunter could easily hit the head of a

squirrel from fifty meters if the sights of his Suomi-gun were adjusted "for his

eye" and the barrel jacket was tightened to the receiver with one or two 0.10

millimeter thick steel washers.

These "accuracy jobs", hunting small-game animals or enemy officers, were the

only instances when KP/-31 was used like a self-loading rifle, the shooter keeping the

gun's buttstock firmly against his shoulder and making use of the sights for aiming.

Full-automatic fire was usually just directed by instinct because smoke of pistol powder

obscured the view ahead of the muzzle after the first or second shot of the burst. The

vast majority of handgun powders contain potassium nitrate or other inorganic salts, being

in fact just "semi-smokeless" propellants.

A Doctrine of Escalation

Semi-automatic shooting was the recommendation during the Thirties. The doctrine was to

use the KP/-31 as a self-loading carbine and save the option of burst-fire for urgency

only. The Winter War experience taught the submachine gunners to shoot bursts of two to

three rounds and during the 1941 - 1944 war it was known that no fewer than five or six 9

mm bullets were a sufficient dose of medicine. Wounded with shorter bursts, enemy soldiers

could often continue fighting when they recovered from the initial shock even if the hits

would prove fatal after a short while.

The Finnish proverb "Siberia shall teach" was true also in the form:

"Siberians shall teach". Many "Russian" invaders in the Winter War of

1939 - 1940 were actually conscripts from Ukraine and other south-western republics of

Soviet Union. Many Russian soldiers of the north-western front in the 1941 - 44 war

against Finland were tough and persistent natives of the Siberian wilds and forests. Some

Finns knew them from the earlier war.

"They were formidable opponents. We were urged to kill almost every Siberian twice,

and most tough boys still a third time", told many Finnish veterans of wars:

"Russian lads, coming against us in closed formation, intoxicated with vodka and

singing Le Internationale, were bunny-boys but the Siberians were born soldiers! We met

them in February 1940 and we learnt to respect those slant-eyed imps... !" Two

bullets were enough for "bunny-boys" but five hits were necessary to dispatch a

Siberian "imp". Sometimes they fought back despite ten or twelve wounds from 9

mm bullets.

Continued: To Part 2/2 >>

Link Page Gunwriters To Part 2/2 of Suomi History

Gunwriters on the Web Suomi SMG History part 1 website URL: http://guns.connect.fi/gow/suomi1.html