<<

guns.connect.fi Link Page>> Gunwriters >>

Issue 4/2000 03.11.2000:

DEFLAGRATION, EXPLOSION and DETONATION:

Three rates of exothermic disintegration

by John R. (Austria)

As you know the guncotton has (nearly) 3 nitro groups (NO2) per cellulose molecule

(guncotton is a really extremely long molecule and therefore it is not exact

stochiometric). These nitro groups are from the nitric acid used in the nitration process.

Nitroglycerol is the ester of nitric acid and glycerol. Guncotton, Nitroglycerol and all

the other higher nitro compounds are in their pure form "high power explosives".

That means they are able to detonate. A detonation is by far more powerful than any

explosion.

For example black powder is impossible to detonate. What happens when black powder is

ignited is following: The fine sulphur and charcoal particles start burning, the generated

heat decomposes the potassium nitrate (it gives off pure oxygen "in nascent

state", as a very reactive free oxygen radical) and so the combustion of the

"fuel" gets faster and faster. When the gaseous reaction products are not able

to "fume off" the pressure and the temperature in the containment will rise

quickly. When the pressure goes up and reaches a point where the container can't hold more

it will explode. Note: The explosion is nothing more than a very rapid expansion of high

pressurized gas.

Nitroglycerol is in its pure form a colourless oily liquid with no odour. When you put a

few drops on a stone plate you can ignite them with a lighter. There will be nothing

dangerous, just a nice flame but no detonation or explosion. Put 1 - 2 (no more than

that!) drops on an anvil (wear ear and eye protection) and strike them directly with a

hammer: extreme loud and powerful detonation! All the higher nitro compounds or nitric

acid esters will react similar when treated that way. But what's now the difference

between detonation and explosion?

Well: these "high explosives", as they are called in the literature, all have

large amounts of chemically bonded oxygen in the molecule. If the amount of energy given

to the explosive is not too high it will start burning. This is called a "deflagration".

A greater mass of burning high order explosive can be very dangerous as it sometimes can

go off in detonation from one moment to another with nearly "no reason". When

more energy is given in a very rapid way (blasting cap) to the explosive, detonation

immediately starts. This is when the molecular structures break up and enormous amounts of

chemical bonded energy are set free by the decomposition of the nitro groups. The rest of

the molecule can be seen as "fuel" that reacts immediately with the oxygen from

the nitro group delivering even more energy. In some high order explosives the detonation

zone moves with a velocity of up to 8500 m/s through the explosive!

The explosives molecules hit by the detonation front are smashed to ions and extremely

reactive radicals ("loose" atoms; not yet bound together to be molecules like H2

or O2) and the whole thing gets plasma-like. Pressures go up to unbelievable 100 000 and

far more atmospheres! Another fact that is difficult to understand but very characteristic

for detonations is that the reaction products move directly to the detonation zone.

Every material (also - and especially - the hardest steel) is "atomized" to fine

particles when hit by this detonation wave. When the detonation is over and no explosive

is left, there are lots of reaction products (mostly H2O, CO2, CO, C, H2 and N) left. What

follows is the explosion (rapid expansion) of the reaction products. Comparing black

powder with dynamite is like comparing an airgun to a high power rifle.

NC powder consists of high order explosives with additions of phlegmatizers. The theory is

that the phlegmatizer is like a shield between the explosive molecules that slows down the

heat transfer and therefore the reaction. Usual NC powder is a mixture of highly nitrated

cellulose and low-nitrated cellulose. Highly nitrated guncotton contain ca. 13 % by weight

nitrogen, while low-nitrated collodion wool contain ca. 11 % N. Guncotton is almost

insoluble in the usual volatile powder solvent, mixture of ethyl ether and ethyl alcohol

while collodion wool is completely soluble, making syrup-like colourless liquid known as

collodion. Mixture of nitrated cellulose is moistened with a volatile solvent when NC

powder is produced. When the solvent is vaporized away, the powder contain

"hairs" or fibres of insoluble guncotton in the plastic-like "matrix"

of dissolved and hardened collodion wool. A solid powder kernel looks like composite

plastic. The very first plastic, celluloid, was actually dissolved (gelatinized) collodion

wool with some camphor added to make celluloid as elastic as the natural ivory, and less

brittle.

American brothers Hyatt invented celluloid in 1869 for billiard balls and piano

keys as an artifical ivory, which was easy to compression mould. In the original NC powder

was a matrix itself the phlegmatizer or shield between more explosive fibres of insoluble

guncotton. There were also some inorganic salts like potassium or barium nitrate added

into old NC powders giving more oxygen and "cooling down" deflagration of the

powder. Some old "semi-smokeless bulk shotgun powders" had those inorganic salts

only as the phlegmatizer. Mixture of guncotton, collodion wool and salts was compressed to

become thick sheets, like cardboard. The sheets were then grated to become irregular

grains and rounded in a rotating "candy drum". Just the surfaces of bulkpowder

kernels were gelatinized by spray of solvent to make them smooth and less prone to imbibe

humidity from ambient air.

Semi-smokeless shotgun powder is older invention than "dense" or gelatinized

smokeless rifle powder. Prussian artillery captain Schultze invented nitrated

sawdust of alder wood, impregnated with potassium and barium nitrates, in 1864. The

"sawdust powder" was too strong medicine for artillery pieces, but it became

soon popular as a shotgun powder. Captain Schultze established his powder plant to the

country of shotgunners, England. German Max Duttenhofer discovered the first

practical semi-smokeless military rifle powder in 1884. This Rottweiler Cellulose

Pulver was nitrolignine & nitrocellulose mixture, nitrated brown charcoal of

alderwood, but it was thoroughly gelatinized.

Frenchman Paul Vieille invented a more stable gelatinized smokeless rifle powder

in 1886, a mixture of guncotton and collodion wool, containing no more nitrolignine.

Russian chemist Dimitri Mendeleyev discovered the optimal ratio of soluble and

insoluble grades of nitrocellulose (with nitrogen content 12.6 %) in 1890 and "the

Mendeleyev's Principle of Controlled Deflagration" in 1891. Swedish Alfred Nobel

and Britons Abel and Noble designed powders like Ballistite and Cordite

in the late 1880s by use of nitroglycerol as a solvent of nitrocellulose. The original

mixture was Gelignite or gelatinized dynamite with up to 60 % percentage of nitroglycerol

- a high explosive - but just a slight addition of some organic phlegmatizer like

"mineral jelly" a.k.a. Vaseline is able to tame the shattering detonation to

become a controlled deflagration. British Rifle Cordite Mk.1. contained 58 %

nitroglycerol.

Detonation wave may become reflected and focused like light. "Shaped charges" of

armor-penetrating warheads or mines were designed just before 2nd World War and applied

for armor-piercing during WW 2. Hand-carried (portative) shaped blasting charges were

first used by Germans in 1940 for capturement of besieged French Maginot Line

strongholds. Principle of shaped charge was discovered by American powder chemist Munroe

in 1880s and improved by German Neumann in early 1900s, but military applications

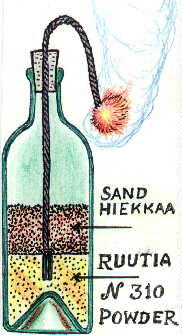

came several decades later. Shaped charge may be a very simple design, like this "V.S.O.P.

Bomb", loaded into a wine or brandy bottle with a concave bottom. Conical shape

of bottom cavity is most efficient for production of a narrow (focused) axial

"detonation jet".

Versatile general-purpose powder VihtaVuori N310 is TRULY versatile, but ANY easily

flammable handgun/shotshell powder with 4000+ Joules per gram of calorimetric energy is

applicable. Blasting cap must be powerful enough to produce detonation. Advisable is to

use bundle of three caps, bound side-by-side. Distance between bottle bottom and surface

of object intented to penetrate should be about equal with diameter of a bottle. More or

less distance or a direct contact on the object shall produce less successful

"focus" of detonation wave and the jet of molten or atomized glass. Perforation

through 50 mm thick steel plate is recorded (or at least rumored). Detonation of common

smokeless powder is able to release all the Infernal Forces: Just a nuclear warhead is

more destructive. (Drawing and caption by PT).

Under "special" circumstances most smokeless powders can be detonated. The

development of modern shooting powders was a long and very dangerous way. Finding the

correct manufacturing process of smokeless gunpowder was often a trial-and-error method

and many guns blew up because of wrong powder "design", or wrong dosage of

correct design.

French chemist Paul Vieille, inventor of first practical smokeless rifle powder

was able to explain nature of detonation in late 1800s, but the comparison between

detonation wave and light was discovered by German mathematician Bernard Riemann

already in 1859. Many times the scientists are predicted inventions much earlier than

existing technology has offered the means to realize their theories. Example given: French

scientist Sadi Carnot predicted arrival of Diesel engine in 1824. First

prototype of Diesel engine was assembled in 1895.

John R.

Gunwriters on the Web DEFLAGRATION, EXPLOSION and DETONATION - Three rates of exothermic disintegration: http://guns.connect.fi/gow/nitro.html